Products

C Purlin Roll Forming Machine

C Purlin Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

C Purlin Roll Forming Machine

C Purlin Roll Forming Machine

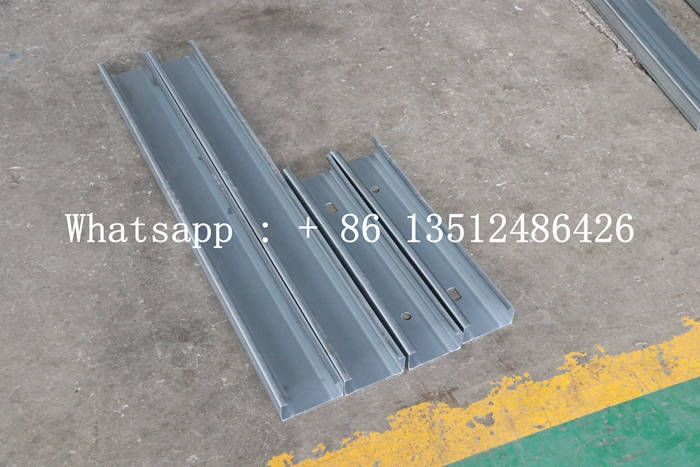

The finished C-shaped steel rolled by the C purlin roll formingmachine has good tensile, bending and compression properties, good flatness, fully automatic fixed-length shearing, automatic punching, high degree of automation, and quick and convenient installation.

The product can be used as the main stress-bearing structure of large and medium-sized industrial and civil buildings. Used in factories, warehouses, locomotive garages, aircraft hangars, exhibition halls, theaters, and sports venues.

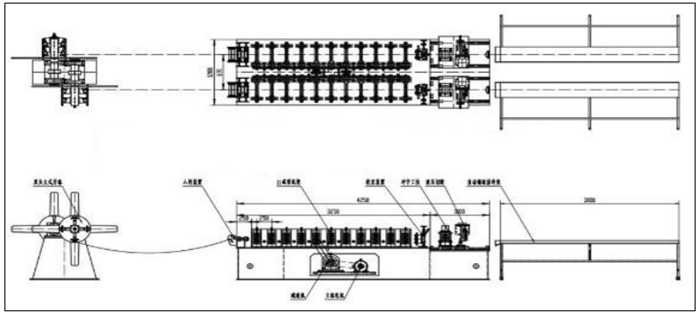

C Purlin Roll Forming Machine

Specification

No. |

Number |

C Purlin Roll Forming Machine |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

| 5. | Dimensions | 9*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

| 13. | Control system | PLC control ( Delta ) |

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 16 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

Feature

1. The spindle adopts a central design with high rigidity and high precision.

2. Equipped with an automatic lubrication system, which can extend the service life of the machine.

3. CNC operating system to complete various processing needs conveniently and quickly.

4. The overall frame adopts a cast structure, which has high strength and stability.

Advantages

1. High efficiency: It can quickly and accurately complete purlin processing of various shapes and improve production efficiency.

2. High precision: Using advanced CNC technology, high-precision processing can be achieved.

3. Diversification: Purlins of various shapes and specifications can be processed to meet different building needs.

4. Automation: Use automated control systems to reduce manual intervention and improve production safety and product quality.

How To Choose

1. Functionality: You should choose a purlin machine that can meet your needs, such as processing speed, processing accuracy, processing range, etc.

2. Durability: Choosing a purlin machine with reliable quality and stable performance can ensure the stability and safety of long-term use.

3. Price: Choosing a purlin machine with reasonable price and high cost performance can ensure your own economic benefits.

So you can choose us, we can meet your all reqiurement.