Products

China Light Keel Roll Forming Machine

China Light Keel Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

China Light Keel Roll Forming Machine

China Light Keel Roll Forming Machine

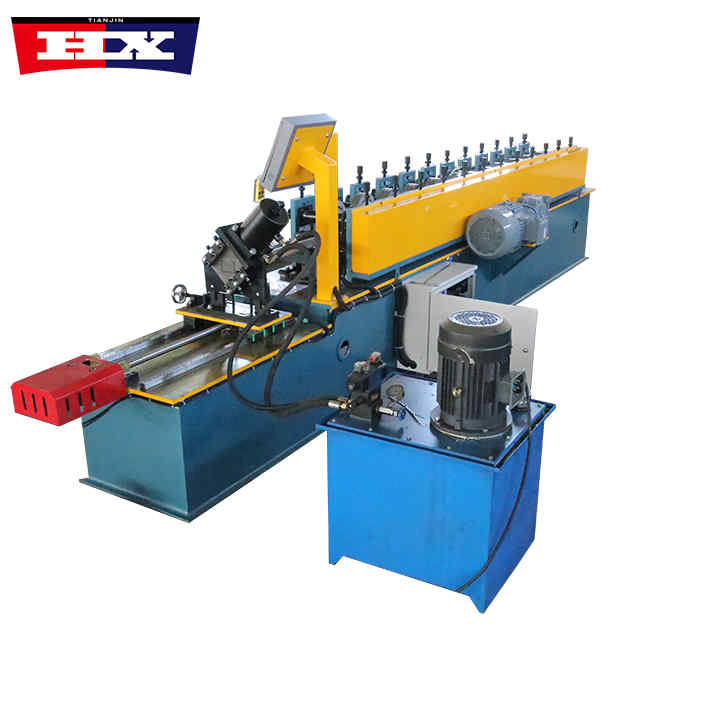

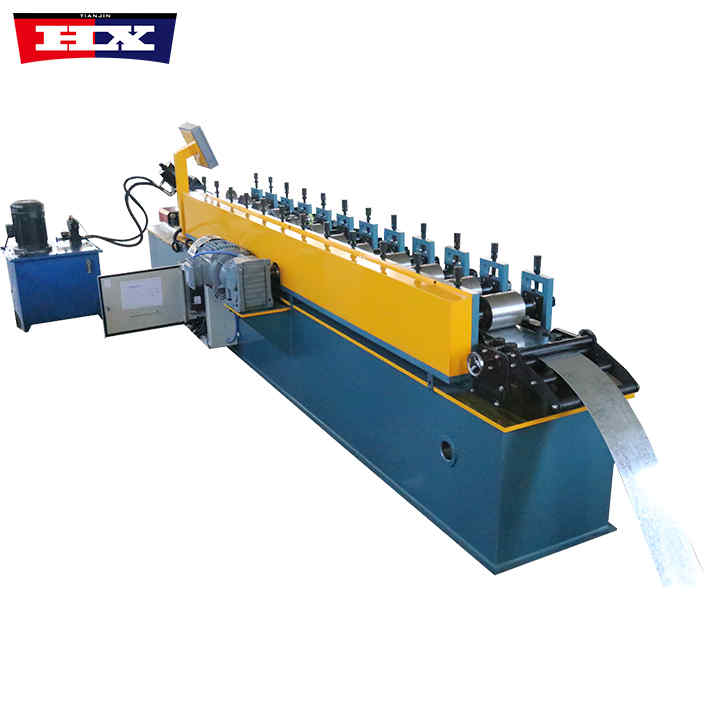

The composition and processing technology of the China light keel roll forming machine. The China light keel roll forming machine is composed of a discharge machine, a guide frame, a forming host, a correction device, a fixed-length cutting part, a receiving table, and an electrical control part. The keel machine uses strip steel as raw material and is formed by continuous cold rolling to produce complex cross-section profiles and cold bending and baking equipment of different specifications. It is controlled by PLC. The processing technology of the keel machine: unloading----straightening----roller forming----cutting----receiving.

1. Keel production requires extremely high accuracy in the relative position of cross-sectional dimensions and features. Switching between different specifications to ensure accuracy over a long period of time is a huge test not only for the design level, manufacturing process, quality control capabilities, and after-sales level. , we have successfully achieved the complex production of multi-specification automatic changeover, multi-specification shearing, material adaptation, and plate thickness application while ensuring the high precision of the product.

2. The process of mold change involves multiple processes such as molding change, mold change, tool adaptation, plate thickness adjustment, etc. The accuracy of the change also saves more adaptation materials.

China Light Keel Roll Forming Machine

Specification

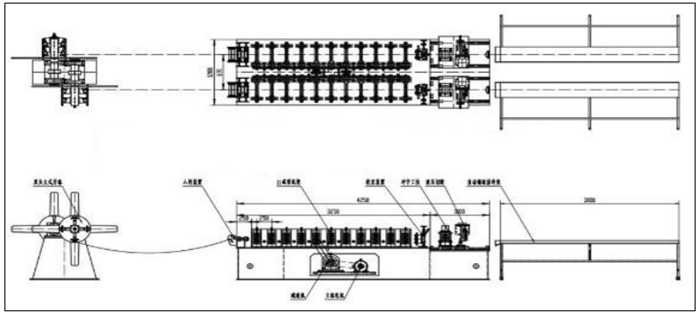

No. |

Number |

China Light Keel Roll Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6.5*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.6t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

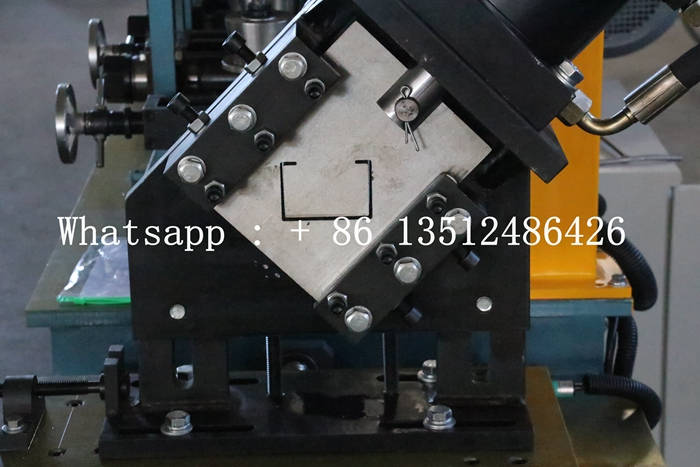

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 12 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Application

1. Light construction field: As a lightweight, high-strength, corrosion-resistant building material, light steel keels are widely used in light construction fields, such as house partitions, sound insulation, heat insulation, fire protection, etc.

2. Partition wall field: The keel machine can produce various specifications and models of light steel keels, which are suitable for partition wall construction, making the partition effect stronger and more stable.

3. Ceiling field: The keel machine can be used to manufacture keel materials for ceilings. It can be processed quickly, accurately and conveniently, providing a solid foundation for the construction of light ceilings.