Products

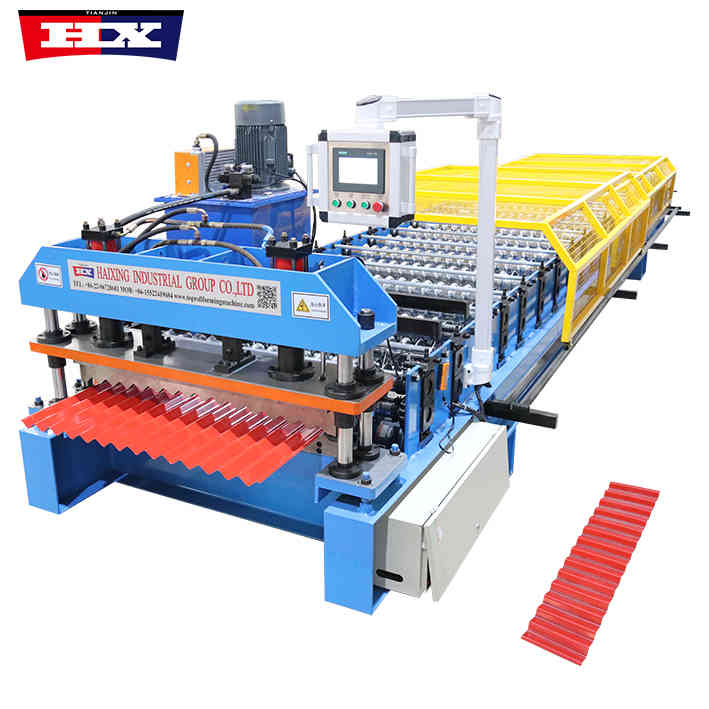

Corrugated Steel Panel Roll Forming Machine

Corrugated Steel Panel Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Steel Panel Roll Forming Machine

Corrugated Steel Panel Roll Forming Machine

The corrugated steel panel roll forming machine is mainly composed of the body, transmission system, tile press system, cutting system, electrical control system and other parts.

1. The fuselage is welded with high-strength steel, which has the characteristics of stable structure and strong earthquake resistance.

2. The transmission system consists of motor, reducer, sprocket, etc., which can provide stable and efficient transmission effect.

3. The tile pressing system includes an upper pressing roller, a lower pressing roller, a forming mold, etc. Through the synergy of the upper and lower pressing rollers, the metal sheet is pressed into corrugated sheets of the required shape.

4. The cutting system consists of blades, knife holders, cylinders, etc., which can achieve precise cutting functions.

5. The electrical control system is responsible for the overall control of the equipment, including starting, stopping, speed regulation, counting and other functions.

Corrugated Steel Panel Roll Forming Machine

Specification

No. |

Number |

Corrugated Steel Panel Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Working Principle

1. First, the metal sheet is fed into the equipment, and driven by the transmission system, the metal sheet enters the tile pressing system.

2. In the tile pressing system, the upper and lower pressing rollers work together to press the metal sheet into corrugated sheets of the required shape.

3. Next, the cutting system accurately cuts the pressed corrugations to meet the requirements of different lengths.

4. Finally, the finished corrugated sheets are discharged through the discharge port to complete the entire processing process.