Products

Glazed Roof Machine

Glazed Roof Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Glazed Roof Machine

Glazed Roof Machine

The glazed roof machine includes: forming host, hydraulic station, discharge rack, forming shears, control box, and discharge rack.

Advantages: light weight, high strength, heavy load bearing, good earthquake resistance

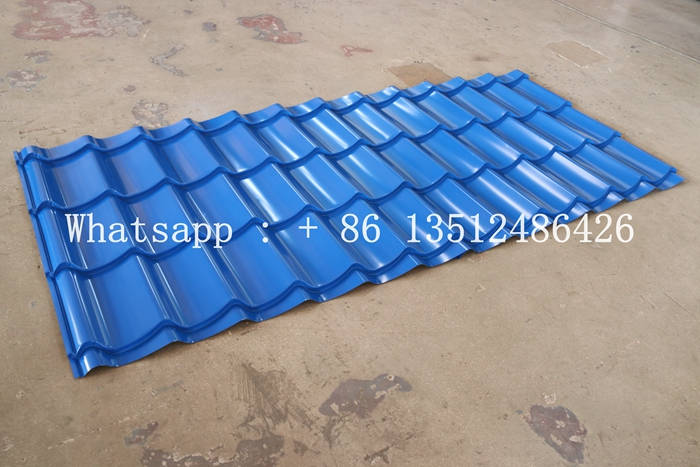

The antique glazed tiles rolled by the glazed tile forming machine and die-formed have the characteristics of beautiful appearance, simple and elegant, elegant and unique shape, and noble taste.

It is widely used in garden-style factories, tourist attractions, pavilions, hotels and villas, exhibition halls, resorts, homes, large and medium-sized enterprise civil buildings, factories, locomotive garages, aircraft hangars, sports venues, exhibition halls, theaters, etc.

Glazed Roof Machine

Specification

No. |

Number |

Glazed Roof Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Operation

1. Adjust the machine

1. Make sure the tile press is powered on and check whether the machine is intact.

2. Adjust the roller distance and pressure as needed to adapt to different types of tiles.

3. Check whether the oil circuit of the tile press is smooth, and clean and maintain it if necessary.

2. Select the tile type

1. Select the appropriate tile type according to your needs.

2. Adjust the machine so that the selected tile type is suitable for production and the quality meets the standard.

3. Loading materials

1. Open the feeding port of the tile press to ensure smooth and orderly feeding.

2. Select appropriate loading tools and methods, and place raw materials on the loading table.

4. Start the machine

1. Start the machine properly according to the production procedures of the tile press.

2. Monitor the operating status of the machine to ensure normal operation of the machine.

3. Make timely adjustments to the machine during the production process as needed to ensure optimal production efficiency and quality.