Products

Steel Roof Sheet Making Machine Price

Steel Roof Sheet Making Machine Price

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Steel Roof Sheet Making Machine Price

Steel Roof Sheet Making Machine Price

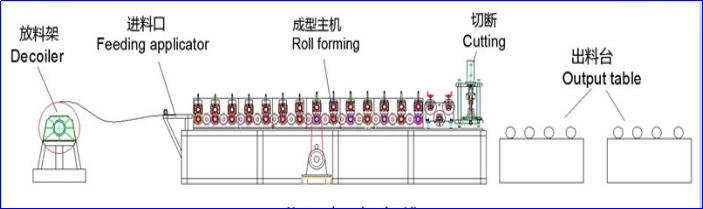

1. The steel roof sheet making machine price is a machine used to press color steel plates. The customer provides the plate pattern or according to the customer's requirements, the tile press factory draws the plate pattern, and presses the color steel plate through cold bending according to the plate pattern.

2. The rolled color steel plate enters the machine at the feeding rack. The sprocket drives the shaft wheel to rotate. After the color steel plate is driven, it is gradually formed after being pressed by wheels. After forming, it reaches the tail of the tile press and passes through the PLC. Control, when the required length is reached, the shearing head falls down and cuts the plate of the required length.

3. The operation of the tile press is very simple. It mainly depends on the operation of the PLC controller of the tile press. The classification of tile press is generally based on the use of the pressed plate. Common ones include corrugated tile press and glazed tile press. , double-layer tile press, trapezoidal tile press, etc.

Steel Roof Sheet Making Machine Price

Specification

No. |

Number |

Steel Roof Sheet Making Machine Price |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Operation

1. Power-on operation

1). Before turning on the machine, you need to confirm that the power supply is turned off.

2). Operators need to check the equipment and work area again to ensure that safety requirements are met

3). Turn on the power switch according to the equipment requirements and start the working state. 4. Wait for the equipment's warm-up time to ensure the normal operation of the equipment.

2. Processing operations

1). Fix the metal material to be processed in the processing area of the tile press equipment.

2). Wear safety protective gear, and operators must choose the correct tools and materials for processing operations.

3). Operate according to the processing requirements, maintain a safe distance during the processing, adjust the position angle and take photos to ensure processing efficiency and quality.

4). During the processing, various screws need to be tightened to prevent safety accidents.

3. Shutdown operation

1). After the processing is completed, the air source needs to be turned off and the power supply must be turned off at the same time.

2). Operators need to perform necessary cleaning and maintenance on the equipment to keep the equipment clean and tidy.