Products

Aluminum Corrugated Machine

Aluminum Corrugated Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Aluminum Corrugated Machine

Aluminum Corrugated Machine

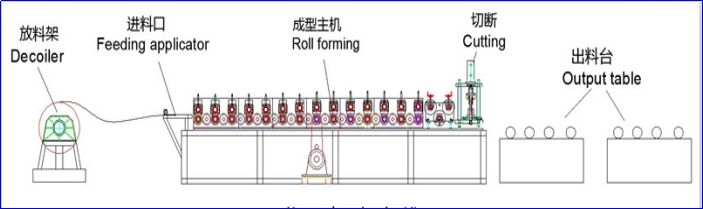

The aluminum corrugated machine is a piece of equipment specially used to process tiles. The basic principle is to hot-press and shape the tiles so that they have a certain hardness and strength to meet specific use needs. The operation process mainly includes: blanking, feeding, pressing, cooling and other links.

Aluminum Corrugated Machine

Specification

No. |

Number |

Aluminum Corrugated Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

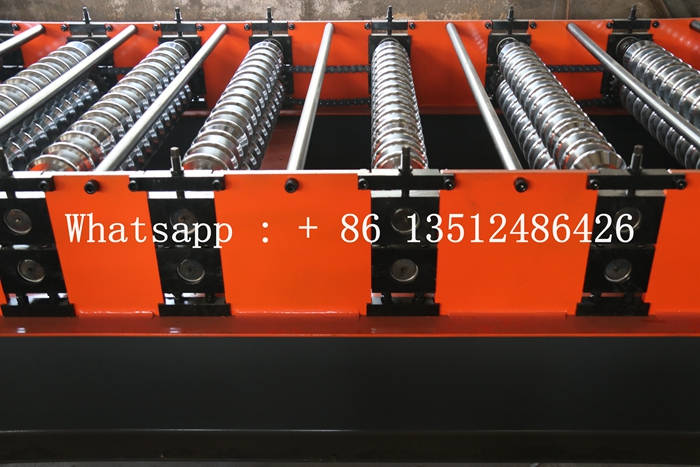

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Operation

1. Equipment debugging

1). Conduct a comprehensive inspection of the equipment to ensure that all parts are installed correctly and without defects.

2). Select and debug the mold according to the tile size and requirements.

3). Adjust equipment pressure, temperature, speed and other parameters according to different tile materials and varieties.

4). Clean the mold to ensure that there is no corrosion or scale on the mold surface.

2. Operation process

1). Turn on the power switch, start the tile press and enter standby mode.

2). Adjust the feeding device to ensure that the tiles can enter the mold smoothly through the feeding device.

3). Put in the raw materials to be processed and start the equipment for processing.

4). Wait for the equipment to automatically complete the processing and cooling process.

5). After completing the processing, take out the finished product and perform necessary packaging and quality inspection.

3. Solutions to common problems

1). How to adjust the mold?

Tiles of different sizes require different molds, which can be accomplished by replacing or adjusting the molds. The adjustment method is to adjust the molds to the appropriate position and then fix them.

2). How to adjust the processing pressure?

The processing pressure is adjusted by adjusting the pressure of the roller. The adjustment method is to gradually increase or decrease the pressure of the roller.

3). How to solve the problem of equipment failure?

Equipment failure may affect production progress and product quality. Common failures include wear of mechanical parts, circuit failures, etc., which require timely investigation and repair. You can contact us anytime.