Products

Automatic C Purlin Roll Forming Machine

Automatic C Purlin Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

Automatic C Purlin Roll Forming Machine

Automatic C Purlin Roll Forming Machine

Specification

No. |

Number |

Automatic C Purlin Roll Forming Machine |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

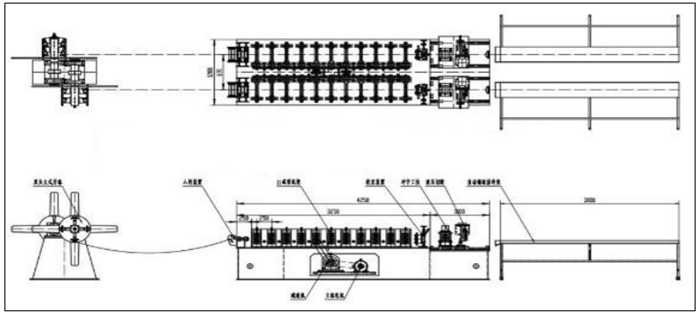

| 5. | Dimensions | 9*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

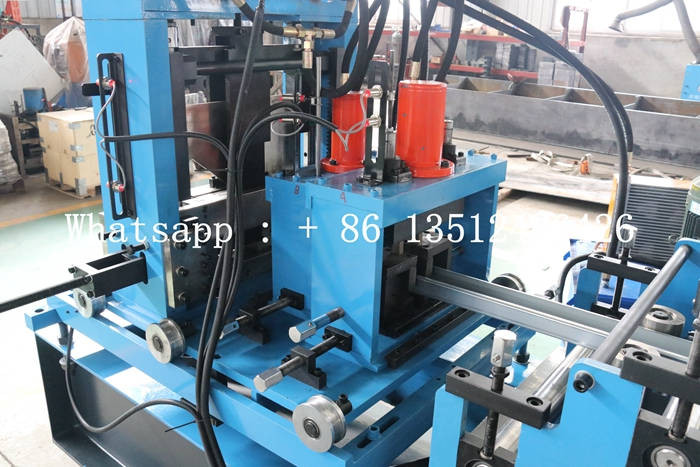

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

| 13. | Control system | PLC control ( Delta ) |

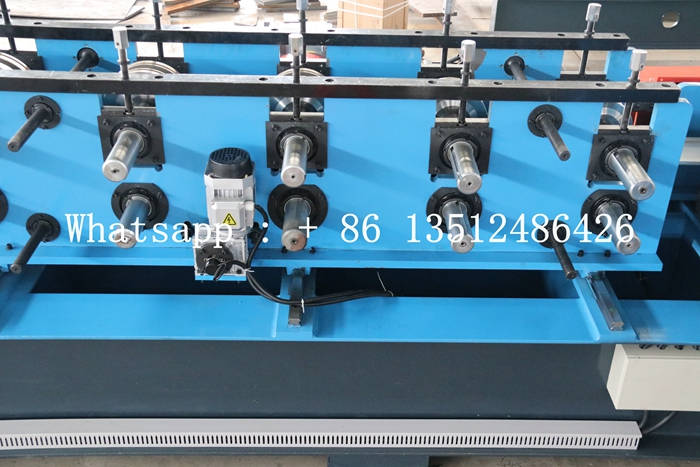

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 16 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

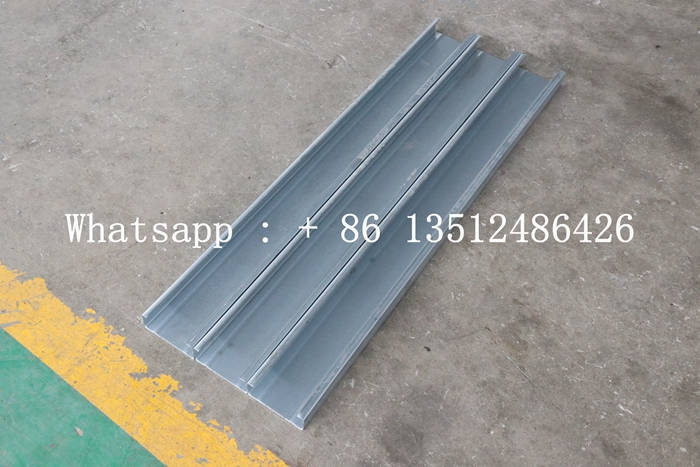

Purlin Advantages

1. Strong load-bearing capacity. As the load-bearing component of the transfer beam, purlins have excellent load-bearing capacity. In the roof structure, it can effectively support the weight and additional load of the entire roof, ensuring the stability and safety of the building structure.

2. Good waterproof performance. Installing a waterproof layer between purlins can effectively prevent rainwater from penetrating and protect the integrity of the building structure. This advantage is especially obvious in roof structures, which can effectively avoid corrosion and damage caused by rain.

3. Good structural adaptability: Purlins can adapt to a variety of building structures and roof shapes, providing designers with greater flexibility and creative space.

4. Convenient construction: The installation and disassembly of purlins is relatively simple, which can speed up the construction progress and reduce construction costs.