Products

C Purlin Forming Machine

C Purlin Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

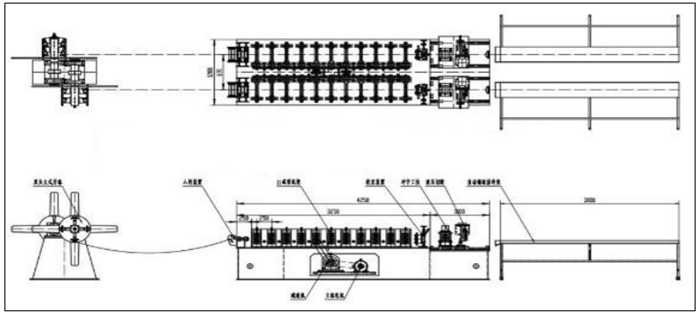

C Purlin Forming Machine

C Purlin Forming Machine

C purlin forming machine is an efficient and intelligent equipment, mainly used to produce steel structure purlins of various specifications. It is characterized by high efficiency, energy saving and environmental protection, providing a new production method for the construction industry.

The working principle of this c purlin machine is to process steel plates into purlins of various shapes and sizes through precision machining. There is no noise or pollution during the production process, and it can complete production tasks efficiently and improve production efficiency.

The advantages of c purlin forming machine include high efficiency, intelligence, environmental protection, energy saving, etc. It can greatly improve the production efficiency of the construction industry and reduce production costs while ensuring product quality and accuracy. In addition, the equipment has good stability and durability and can meet production needs in various complex environments.

C purlin forming machine have important application value in the modern construction industry. It can not only produce steel structure purlins of various specifications, but also perform various complex mechanical processing. It is widely used in bridges, highways, high-rise buildings and other fields, and has made important contributions to the development of the modern construction industry.

C Purlin Forming Machine

Specification

No. |

Number |

C Purlin Forming Machine |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

| 5. | Dimensions | 9*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

| 13. | Control system | PLC control ( Delta ) |

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 16 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

Feature

1. The spindle adopts a central design with high rigidity and high precision.

2. Equipped with an automatic lubrication system, which can extend the service life of the machine.

3. CNC operating system to complete various processing needs conveniently and quickly.

4. The overall frame adopts a cast structure, which has high strength and stability.

Advantages

1. High efficiency: It can quickly and accurately complete purlin processing of various shapes and improve production efficiency.

2. High precision: Using advanced CNC technology, high-precision processing can be achieved.

3. Diversification: Purlins of various shapes and specifications can be processed to meet different building needs.

4. Automation: Use automated control systems to reduce manual intervention and improve production safety and product quality.