Products

Corrugated Roll Former Machine

Trapezoidal Sheet Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Roll Former For Sale

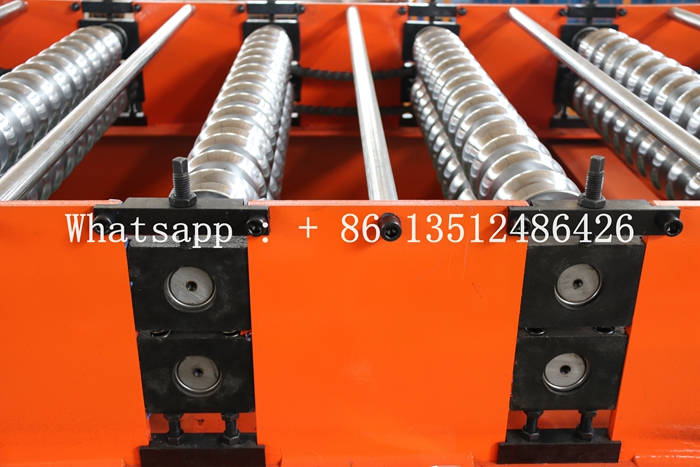

Corrugated Roll Former Machine

The working principle

Mainly to shape the metal sheet through the pressure between the upper and lower rollers. When the metal sheet passes between the upper and lower rollers, it is subject to pressure and bends and deforms, thereby obtaining the desired shape. During the molding process, the corrugated roll former machine adopts an advanced control system to ensure the improvement of molding accuracy and stability.

Corrugated Roll Former For Sale

Specification

No. |

Number |

Corrugated Roll Former For Sale |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Machine Composition

1. The roller is the core component, and its quality directly affects the forming effect and product quality.

2. The base is the main structure that supports the entire equipment and requires high rigidity and stability to ensure smooth and accurate operation of the equipment.

3. The transmission system is the power part that drives the roll and requires high precision and reliability.

4. The control system is a key part of realizing automated production. It can monitor and adjust the equipment in real time to ensure the smooth progress of production.