Products

Corrugated Roll Making Machine

Corrugated Roll Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Roll Making Machine

Corrugated Roll Making Machine

1. High efficiency: Corrugated roll making machine adopts advanced transmission system and molding technology, which greatly improves the production efficiency of the equipment.

2. Stable: The equipment has a solid structure, stable operation, and can work continuously for a long time to meet the needs of large-scale production.

3. Easy to operate: The control system adopts PLC control, which is easy to operate and maintain, and reduces labor costs.

4. Diversification: Corrugated roll making machine can produce corrugated tiles of various specifications to meet the needs of different architectural styles.

Corrugated Roll Making Machine

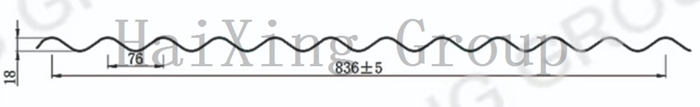

Specification

No. |

Number |

Corrugated Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. Commercial buildings usually require a unique appearance and image to attract more customers. The tile press can customize tiles of different colors, shapes and patterns to meet various personalized needs of commercial buildings.

2. Through the creative design and high-quality production of tiles, commercial buildings can establish a brand image and increase brand recognition and appeal.

3. The tiles produced by corrugated roll making machine have high density and strength, which can provide reliable waterproof and wind resistance, protecting commercial buildings from severe weather.

4. Corrugated roll making machine can produce tiles with thermal insulation properties, reducing the energy consumption of commercial buildings and improving energy-saving effects.

Introduction

Corrugated roll making machine is widely used in various fields of the construction industry, such as industrial plants, warehouses, agricultural greenhouses, residential buildings, etc.

In these fields, corrugated tiles have been widely used due to their excellent waterproof, anti-corrosion, fire prevention, heat insulation and other properties.

In short, Corrugated roll making machine, as an efficient, stable and easy-to-operate construction equipment, plays an important role in the construction industry. With the continuous advancement of science and technology and the continuous changes in the market, the 600 type tile press will continue to be upgraded and optimized to provide the construction industry with more high-quality and efficient production equipment. At the same time, as the concept of environmental protection is deeply rooted in the hearts of the people, the 600 type tile press will pay more attention to improvements in environmental protection and energy saving in the future, contributing to the development of green buildings.