Products

Corrugated Steel Roofing Sheet Machine

Corrugated Steel Roofing Sheet Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Steel Roofing Sheet Machine

Corrugated Steel Roofing Sheet Machine

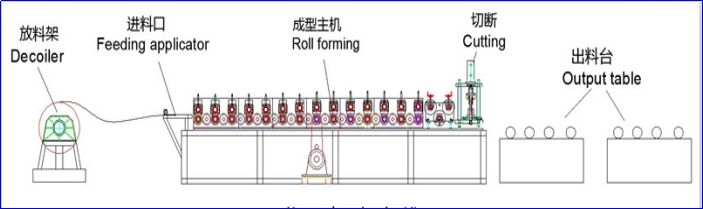

The working principle of the corrugated steel roofing sheet machine mainly relies on the hydraulic system and the pneumatic system. During the working process, the hydraulic system first drives the main shaft of the tile press to rotate, while the pneumatic system controls the up and down movement of the tile press mold. When the tile raw materials enter the mold, the spindle rotates to press the raw materials into tiles of the desired shape. Then, the next piece of raw material is fed into the mold through the automatic feeding system to complete the next round of pressing work. During the entire process, the equipment will automatically perform operations such as cutting and counting to achieve automated production.

Corrugated Steel Roofing Sheet Machine

Specification

No. |

Number |

Corrugated Steel Roofing Sheet Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Features

1. High efficiency: The corrugated steel roofing sheet machine adopts advanced technology and design, which can quickly and efficiently produce color steel plates of various specifications, thus improving production efficiency and reducing production costs.

2. High precision: The corrugated steel roofing sheet machine adopts a high-precision CNC system and transmission system to ensure the size and shape accuracy of the color steel plate and reduce the trouble of subsequent processing and adjustment.

3. Easy to operate: The corrugated steel roofing sheet machine adopts an intelligent control system and a humanized operating interface, making the operation easier and faster, reducing the labor intensity and technical difficulty of workers.

4. High reliability: The corrugated steel roofing sheet machine adopts high-quality materials and components and undergoes rigorous testing and inspection to ensure the reliability and stability of the equipment and reduce the failure rate and maintenance costs.

5. High versatility: The corrugated steel roofing sheet machine can produce color steel plates of various specifications and shapes. It is suitable for a variety of construction and industrial fields and has a wide range of applications and market demands.