Products

Decoiler Straightener

Decoiler Straightener

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Decoiler Straightener

Decoiler Straightener

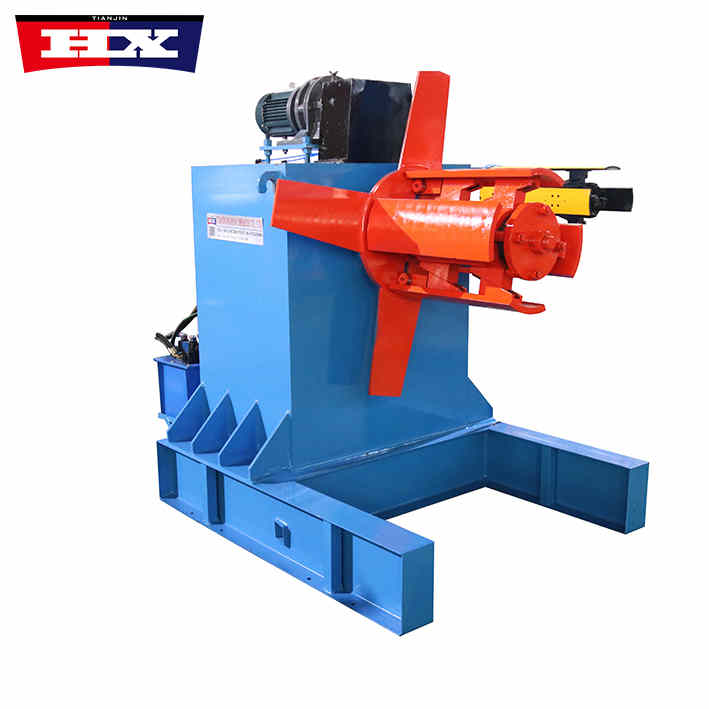

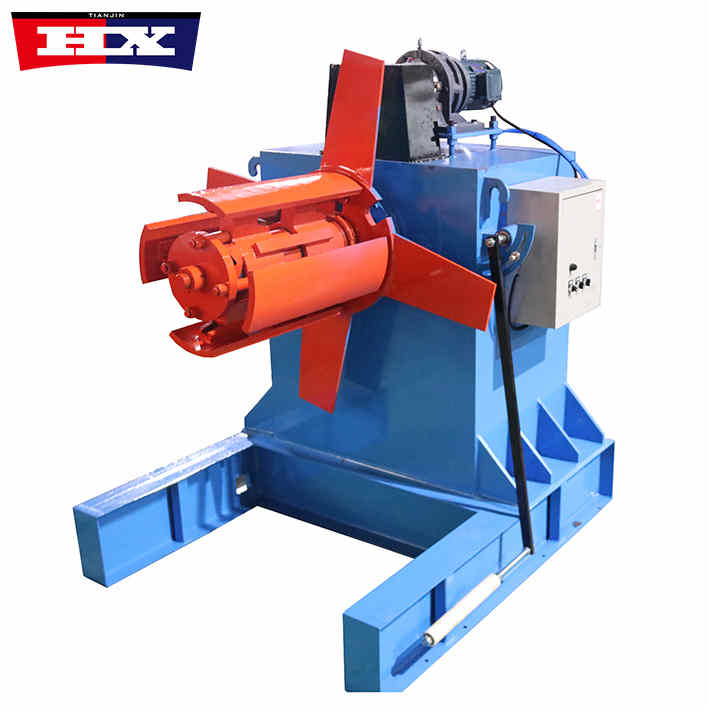

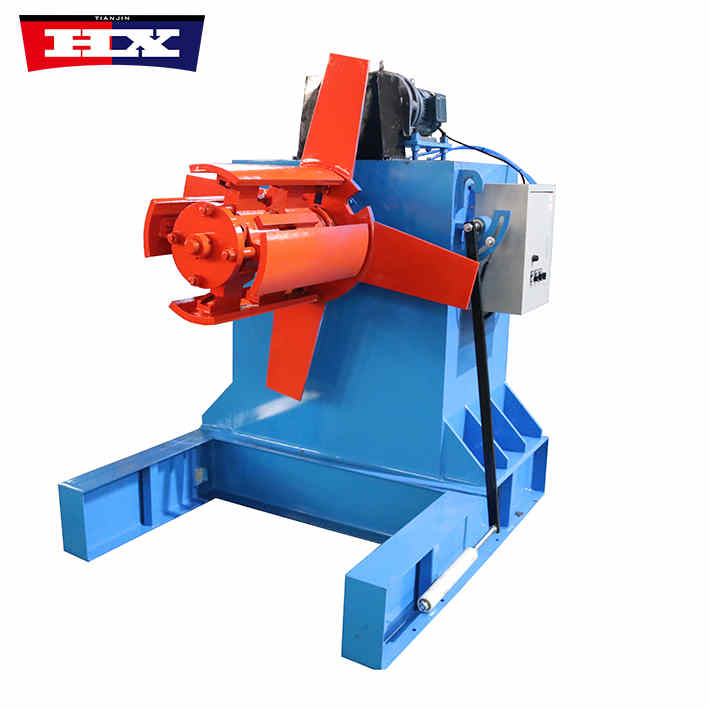

The decoiler straightener is a mechanical equipment that is usually used to decoil various coils such as steel coils, aluminum coils, copper coils, etc. It is a very important equipment in the processing of various metals, plastics, paper, cloth and other materials. It is widely used. Used in different industries.

The body of the decoiler straightener is a welded box-shaped structure. The variable frequency speed regulating motor drives the reel shaft after decelerating through the gear box to provide the main power for the uncoiler. The drum of the uncoiler is a hollow shaft, which is supported on the gear box through two bearings, and a transmission spur gear is installed between the bearings. The gearbox is lubricated by forced lubrication and is equipped with two constant-speed motors for a closed-loop oil lubrication system. The mandrel is a cantilever structure, and its front end is supported by an external support bearing during uncoiling to maintain the rigidity and stability of the uncoiler.

The core shaft of the decoiler straightener is connected to four sector-shaped plates through inclined dovetail grooves on the four end faces. Each sector-shaped plate is prevented from axial movement by a radial slide at the rear end, but it can expand and contract in the radial direction. A rotating oil cylinder is connected to the rear end of the drum shaft. The piston rod of the oil cylinder drives the front-end quadrilateral shaft to slide axially through the tie rod in the center of the drum shaft, thus driving the sector plate to expand and contract radially. The nominal diameter of the drum can be increased by adding four additional sector plates. The uncoiler frame can move on the guide rail of the machine base and is driven by a hydraulic cylinder to achieve center position control. In order to enhance the stability of the drum, a support arm device is designed on the head of the drum. When there is a steel coil on the drum, the support arm is driven by an oil cylinder to support the head of the drum. The support arm is normally retracted without affecting the stability of the drum. Steel coil is rolled up.

Specification

No. |

Number |

Decoiler Straightener |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 5 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |