Products

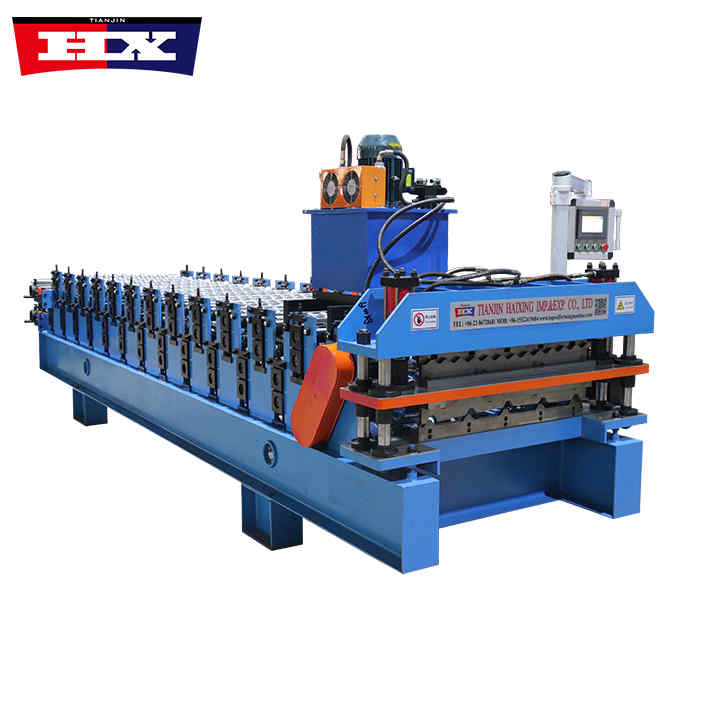

Double Layer Forming Machine

Double Layer Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Double Layer Forming Machine

Double Layer Forming Machine

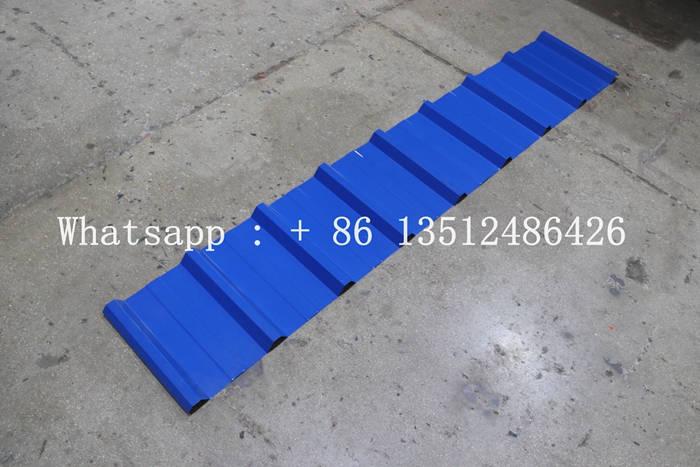

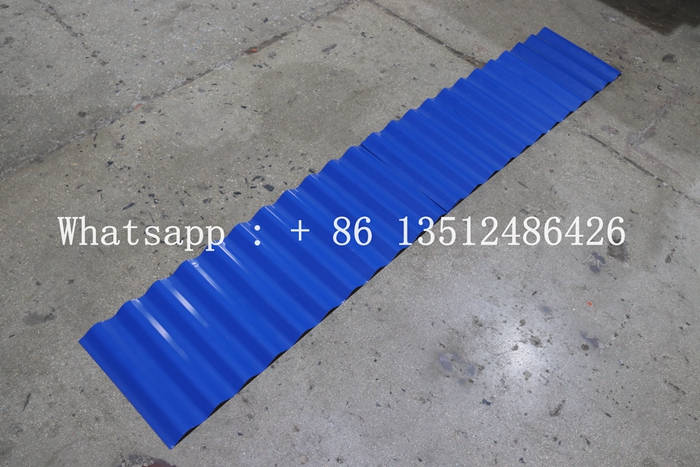

1. Cutting: Cut the color steel plate according to the required size, usually using a cutting machine.

2. Forming: The cut color steel plates are fed into the double-layer tile press, and through the action of a set of rollers, the color steel plates are gradually formed into the required tile shape.

3. Embossing: During the molding process, by installing pattern molds on the rollers, various patterns can be embossed on the surface of the tiles to increase their aesthetics.

4. Groove pressing: In the next set of rollers of the double-layer tile press, you can choose to install a notch mold to press the tiles on one side out of the groove to improve the interlocking ability between the tiles.

5. Cutting: After the forming and embossing are completed, the continuously formed tiles are cut into the required length by a cutting machine or shearing machine.

6. Stacking: Stack the cut tiles to facilitate subsequent packaging and transportation.

Double Layer Forming Machine

Specification

No. |

Number |

Double Layer Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows |

13 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Features

1. The plate shape is flat and the double layer forming machine are smooth.

2. After technical research, there are no waves on the small edges of the plate, and the overlap is accurate and reasonable, which can effectively prevent water and rain.

3. Advanced technology: This double layer forming machine uses continuous coil production, and after cold bending and forming, the parts are cut to precise lengths and formed in one go. The shapes are regular and the lengths are accurate and consistent. The molded workpiece has good appearance and high strength.

4. High productivity: This double layer forming machine only requires 1-2 people to operate, the operation is simple and the labor intensity is low. The normal operating speed is: 10-15 meters/minute.

5. High reliability: The main components of the hydraulic, pneumatic and electrical systems of this double layer forming machine are all imported high-quality components, with stable performance and high reliability.