Products

Double Layer Roll Forming Machine

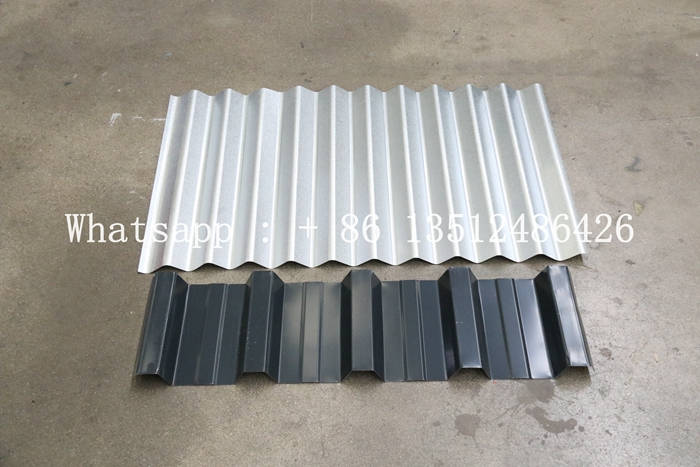

Double Layer Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

1. Improve strength and lifespan

The biggest advantage of the double-layer tile press is that it can significantly improve the strength and life of the color steel tiles. By pressing two layers of color steel tiles together, the double-layer tile press can increase the thickness and weight of the tiles, thereby improving the pressure resistance, wind resistance, corrosion resistance and other properties of the color steel tiles. This increased strength and longevity can greatly reduce the frequency of replacement and maintenance costs of color steel tiles.

2. High efficiency and energy saving

The double-layer tile press also has the advantage of high efficiency and energy saving. Because the double-layer tile press uses advanced hydraulic technology and high-strength materials, it can produce high-quality color steel tiles at faster speeds and with higher efficiency. This efficient production method can reduce production costs and improve production efficiency, while also reducing energy consumption and carbon emissions.

3. Wide scope of application

The double-layer tile press has a very wide range of applications. It can be applied to various color steel tiles of different materials and thicknesses, giving it a wider range of applications. For example, the double-layer tile press can be used to produce various types of color steel tiles for construction, color steel tiles for automobiles, color steel tiles for home appliances, etc. In addition, the double-layer tile press can also be applied to a variety of different working environments and climate conditions, and has very high adaptability.

Double Layer Roll Forming Machine

Specification

No. |

Number |

Double Layer Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows |

18 13 |

| 19. | Size | 9000mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Operation

1. Install equipment

Before using the tile press, you first need to install the equipment. You need to pay attention to the following points when installing:

1). Prepare installation tools, including wrenches, screwdrivers, lifting equipment, etc.

2). Environmental requirements: Because the work of the tile press requires noise and vibration, the installation location should be far away from residential areas or office areas. It is best to choose a relatively isolated place.

3). The installation of equipment should be carried out by professional technicians to ensure the installation quality and safety of the equipment.

2. Preparation work

Before starting to operate the tile press, you need to make the following preparations:

1). Prepare the materials required for the tile press, including steel plates, press tiles, screws, etc.

2). Check whether the equipment is operating normally and whether any parts are loose or abnormal.

3). Turn on the power supply and lubrication system of the tile press.