Products

Double Layer Trapezoidal Roll Forming Machine

Double Layer Trapezoidal Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Double Layer Trapezoidal Roll Forming Machine

Double Layer Trapezoidal Roll Forming Machine

1. The double layer trapezoidal roll forming machine is economical and affordable. It can combine two types of equipment into one, which saves floor space. Moreover, the cost of double-layer is much lower than that of two single-layer machines, making it suitable for users in small sites.

2. The double layer trapezoidal roll forming machine adopts a double-layer design, which can be used for two purposes. It occupies a small area, is convenient for transportation, and saves costs.

3. The double layer trapezoidal roll forming machine equipment adopts high-level automatic control software to realize production information management. The entire unit automation control system adopts a highly integrated network to improve the performance of the automation system, as well as operation, maintenance, maintenance, and mechanical debugging and molding. Advantages include easy replacement.

Double Layer Trapezoidal Roll Forming Machine

Specification

No. |

Number |

Double Layer Trapezoidal Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

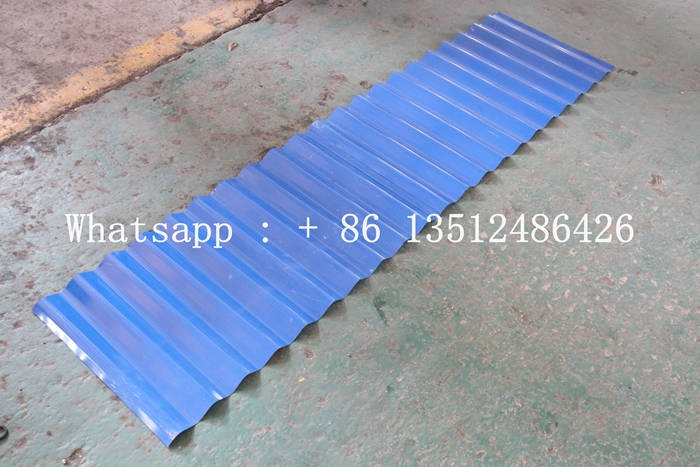

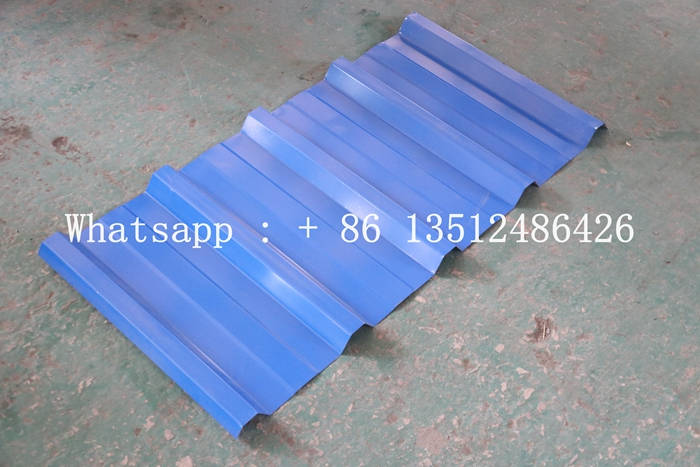

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows |

13 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Operational Matters

1. Electricians must understand the wiring of the workshop and the type and performance of the color steel tile press equipment. If you do not have a clear understanding of the performance of the color steel tile press equipment, you cannot use it at risk.

2. The electrician should set a time to check the condition of the motor and electric control console. During the inspection, the electrician should see the situation and deal with it as necessary. When checking the power of the motor, first check that there is no power, and then check with the back of your hand.

3. In addition to the electrical facilities for temporary construction work, no temporary wires can be set up, lights, tools, welding equipment and other stable sockets cannot be hung randomly. The previous wires cannot be changed at will.