Products

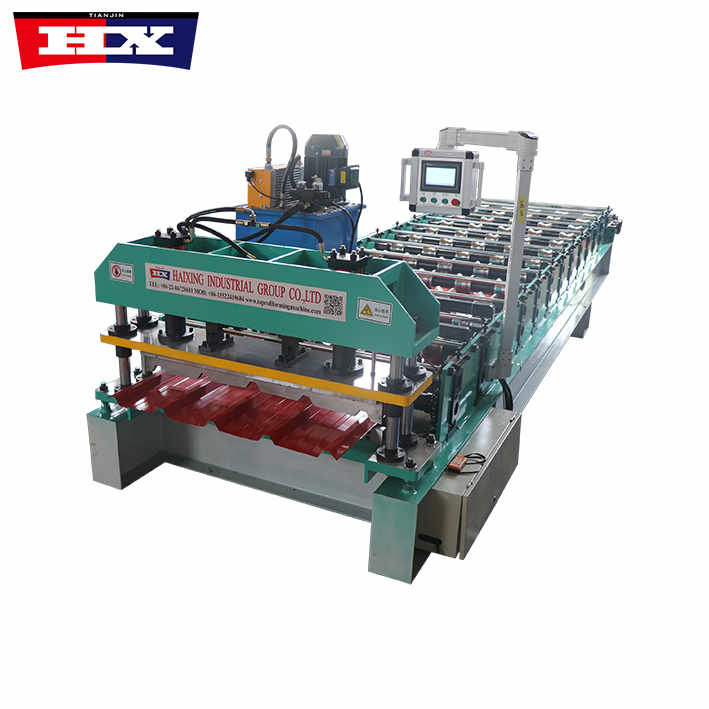

Trapezoidal Galvanized Sheet Making Machine

Trapezoidal Galvanized Sheet Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Galvanized Sheet Making Machine

Trapezoidal Galvanized Sheet Making Machine

Trapezoidal Galvanized Sheet Making Machine

Specification

No. |

Number |

Trapezoidal Galvanized Sheet Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Company Advantages

1. Choose the right material: high hardness, good temperature and pressure bearing, stable performance and long use time. The material is not easy to deform, corrode or oxidize, and has a long service life.

2. High mold opening accuracy: using precision processing equipment and wire cutting processing

3. Timely delivery: Strictly control the quality inspection process, good quality, good durability and fast delivery

Machine Advantages

1. Efficiency: The trapezoidal galvanized sheet making machine adopts advanced production technology, has high production efficiency and can meet the needs of mass production.

2. Energy saving and environmental protection: The trapezoidal galvanized sheet making machine adopts advanced energy-saving technology, which can effectively reduce energy consumption. At the same time, the noise and dust generated during its production process are relatively small, which is beneficial to environmental protection.

3. Versatility: The trapezoidal galvanized sheet making machine can produce trapezoidal tiles of various shapes and specifications to meet the needs of different fields.

4. High precision: The trapezoidal galvanized sheet making machine uses high-precision molds and molding technology to produce trapezoidal tiles with high precision and good surface quality.

Application

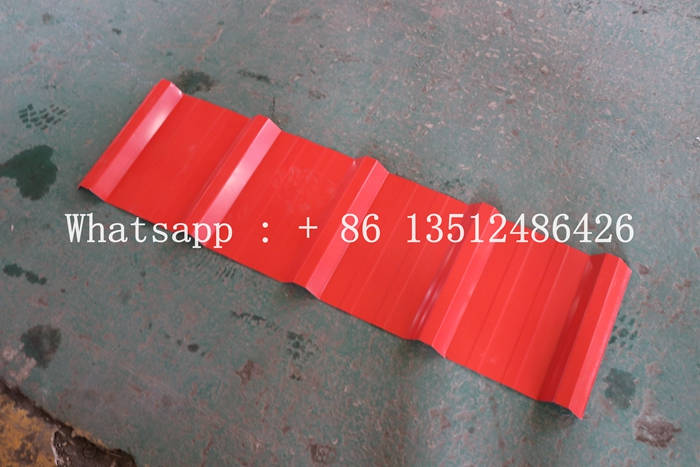

1. Construction field: The trapezoidal galvanized sheet making machine is mainly used to produce trapezoidal tiles for various constructions, such as flat to slope, roof waterproofing, etc.

2. Garden landscape: The trapezoidal galvanized sheet making machine can also be used to produce trapezoidal tiles for various garden landscapes, such as flower stands, walls, pavilions, etc.

3. Other fields: such as highways, railways, water conservancy and other infrastructure construction also need to use trapezoidal tile forming machines.

Machine Maintian

The trapezoidal galvanized sheet making machine requires regular maintenance and upkeep during use to ensure the normal operation of the equipment and extend its service life. Common maintenance work includes replacing wearing parts, cleaning the surface of the equipment, and checking whether various parts of the equipment are loose.