Products

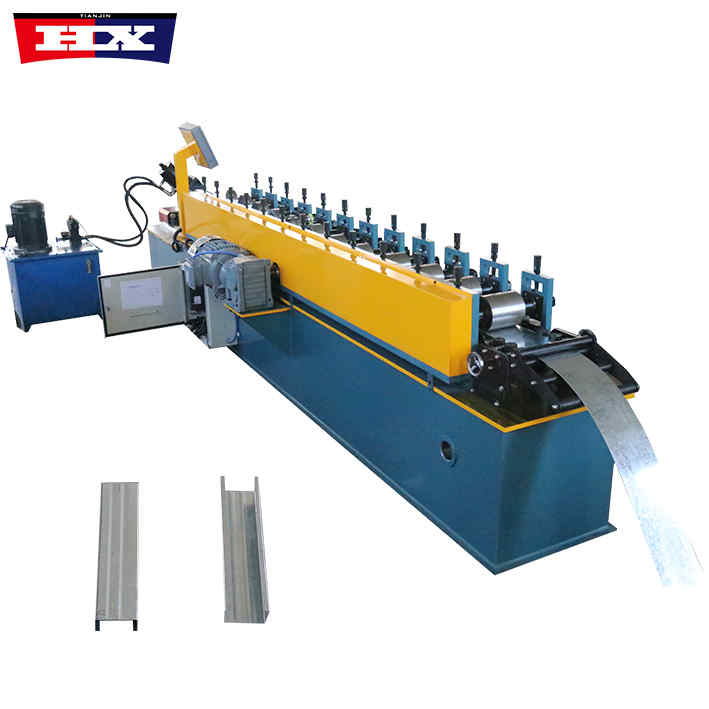

Light Steel Keel Roll Forming Machine

Light Steel Keel Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Light Steel Keel Roll Forming Machine

Light Steel Keel Roll Forming Machine

The light steel keel roll forming machine, also known as the light steel keel machine, is a machine specially used to process light steel keels. Its main working principle is to process thin steel plates into steel keels of different shapes through pressure and cutting to facilitate use in construction projects.

Light Steel Keel Roll Forming Machine

Specification

No. |

Number |

Light Steel Keel Roll Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

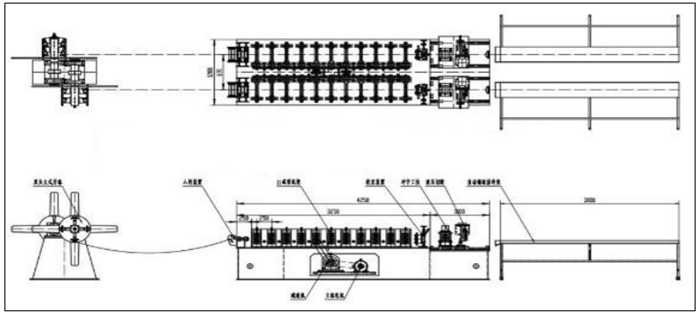

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6.5*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.6t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

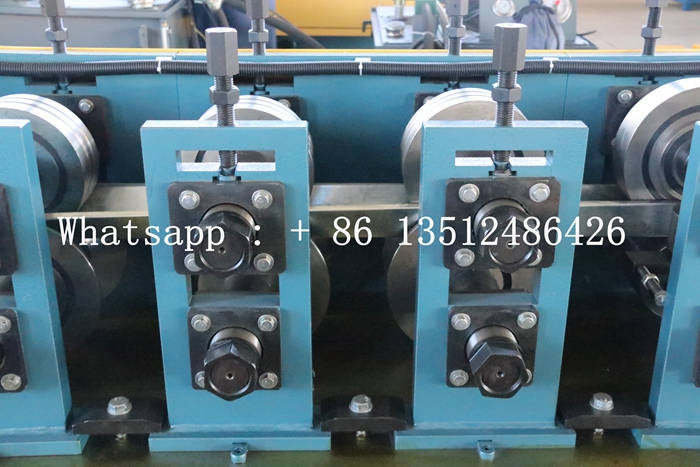

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 12 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Use

1. Building construction:

Light steel keels are widely used in construction, such as light steel structures, walls, ceilings, etc. Therefore, the keel machine plays a decisive role in construction.

2. Home decoration:

With the continuous development of light steel keels, keel machines are gradually being used in home decoration, such as wall lining production, roof panel production, etc.

Effect

1. Improve the quality of building construction:

The keel machine can process light steel keels into standard sizes and shapes, improving the quality and efficiency of construction.

2. Reduce labor costs:

Using a keel machine to process and produce light steel keels can greatly reduce labor costs and improve operating efficiency.

3. Improve construction safety:

Although light steel keels are lightweight, they have sufficient strength and toughness to a certain extent, which can provide additional safety guarantees for building construction.