Products

Machine To Make Corrugated Metal Sheet

Machine To Make Corrugated Metal Sheet

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Machine To Make Corrugated Metal Sheet

Machine To Make Corrugated Metal Sheet

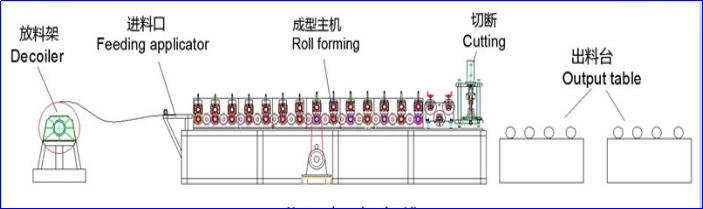

The working principle of the machine to make corrugated metal sheet mainly involves transmitting pressure to the oil cylinder through the hydraulic system, pushing the upper and lower molds to close, and pressing and forming the metal sheet. During the pressing process, the machine adopts a digital control system, which can realize automatic control and adjustment, improving production efficiency and product quality.

Machine To Make Corrugated Metal Sheet

Specification

No. |

Number |

Machine To Make Corrugated Metal Sheet |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

How To Operate

1. Preparation: Confirm that the machine power supply is connected and powered on. Check whether all parts of the machine are operating normally, such as transmission belts, bearings, etc. Check whether the raw materials are ready.

2. Adjust the mold: According to the required tile specifications, select the corresponding mold and install it on the machine. Make sure the mold is installed securely. Adjust the mold position and pressing depth to accommodate different tile shapes and thicknesses.

3. Adjust pressure and speed: Adjust the machine parameters according to the required pressure and speed. Generally speaking, lower pressure and speed are suitable for thinner tiles, while higher pressure and speed are suitable for thicker tiles. Make adjustments according to actual conditions.

4. Start pressing: Put the raw materials into the feed port of the machine, and send the raw materials into the mold through the machine's conveying system. Start the machine and start pressing the tiles.

5. Check the quality: During the pressing process, always check whether the quality and shape of the tiles meet the requirements. If any problems are found, stop the machine for maintenance and troubleshooting in time.

6. Collect finished products: The pressed tiles will be discharged from the discharge port of the machine. The finished tiles are collected using a collecting device, processed and packaged.

7. Cleaning and maintenance: After using the fully automatic tile press, clean the residue inside and outside the machine in time to keep the machine clean and tidy. Perform regular maintenance, check the wear and tear of various parts of the machine, and make necessary replacements and repairs.