Products

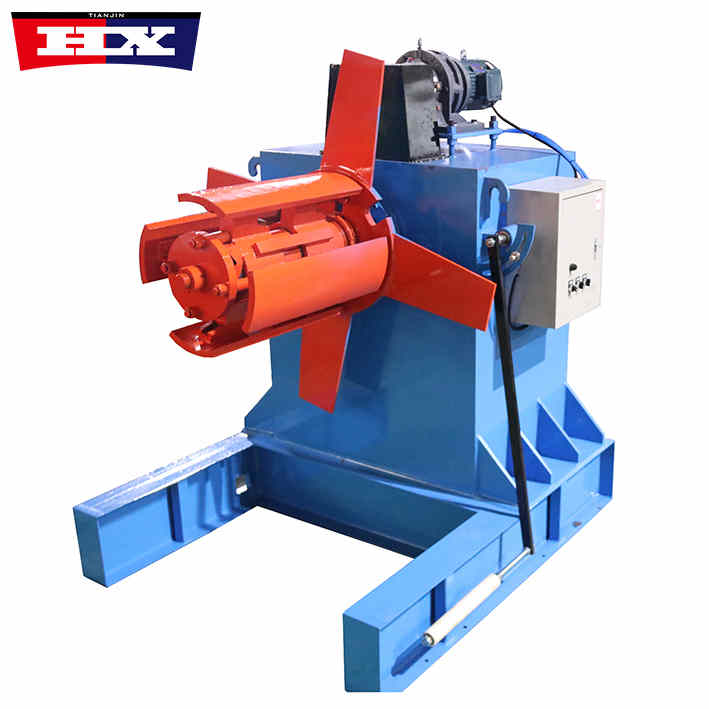

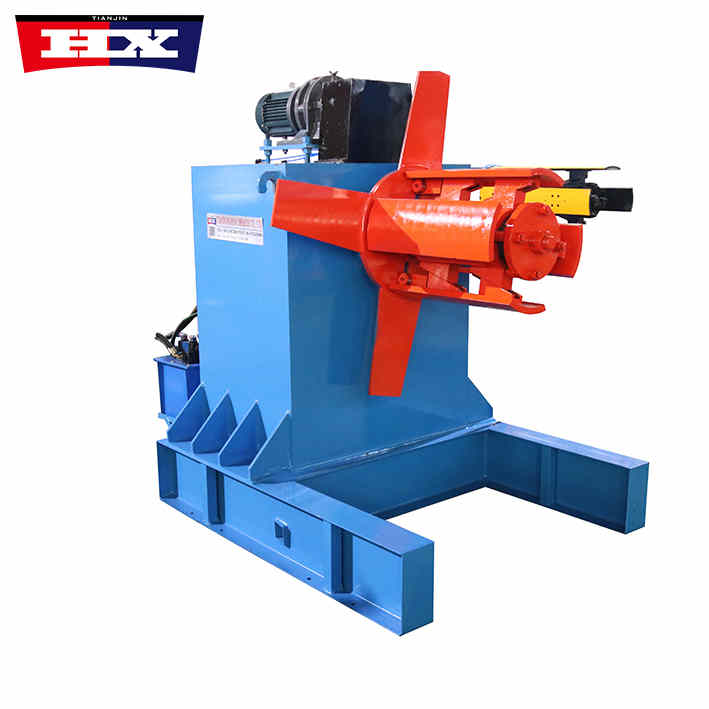

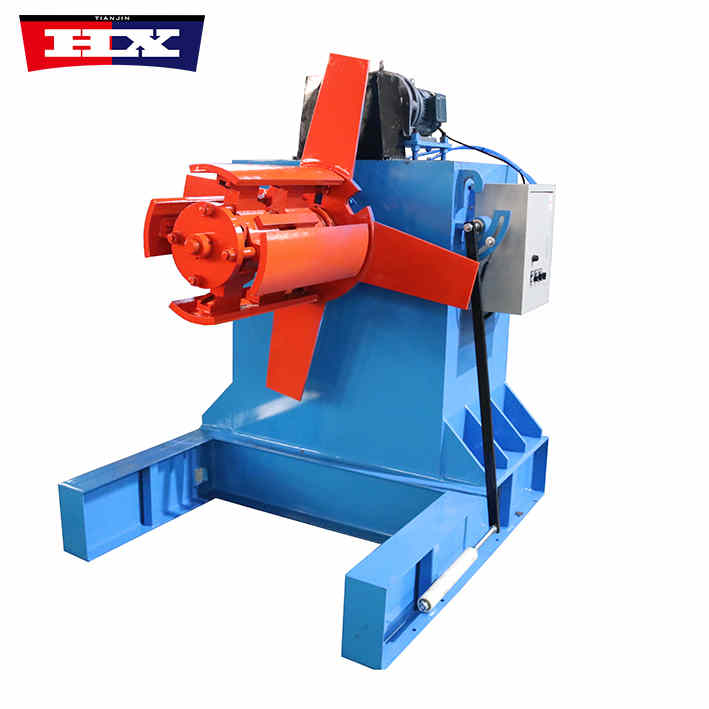

Metal Decoiler

Metal Decoiler

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Metal Decoiler

Metal Decoiler

The automatic metal decoiler is a mechanical device used to automatically unroll roll-shaped metal sheets. It is widely used in sheet processing, packaging, transportation and other fields.

Specification

No. |

Number |

Metal Decoiler |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 5 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Operation

1. Preparation stage

Check whether the power connection is normal and make sure the power switch is turned off.

Check whether there are any looseness or abnormalities in various parts of the machine, and make timely adjustments if necessary.

Make sure the roll material is placed on the loading rack and the roll core is aligned with the feed opening of the machine.

2. Start-up stage

Turn on the power switch and start the machine.

Observe whether the machine is operating normally and whether there are any abnormal sounds or vibrations.

After confirming that the machine is running smoothly, proceed to the next step.

3. Operation stage

Introduce the belt head into the feed port and introduce it into the machine through the traction device.

Adjust the pressure and speed of the leveling wheel to ensure that the metal plate is gradually flattened under the action of the leveling wheel.

According to the required size, adjust the position and size of the shearing device to cut the metal sheet to the required length.

Observe the operation of the machine to ensure that the shearing and flattening results meet the requirements.

4. Ending stage

Press the stop button to stop the machine.

Place the flattened metal sheet roll on the unloading platform and the operator will take it away.

Clean the remaining metal debris and debris on the surface of the machine to keep the machine clean.

Turn off the power switch to end this operation.

5. It should be noted that when operating the automatic coil uncoiler, the operating procedures should be strictly followed to avoid safety accidents. At the same time, regular maintenance and upkeep of the machine is required to ensure normal operation of the machine.