Products

Metal Roof Sheet Making Machine

Metal Roof Sheet Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Metal Roof Sheet Making Machine

Metal Roof Sheet Making Machine

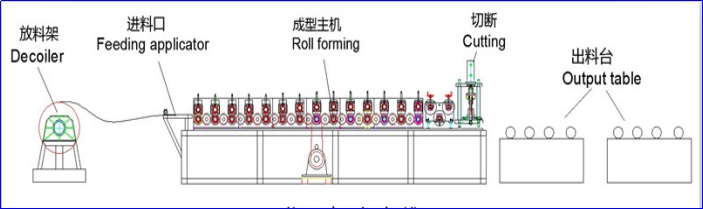

Metal roof sheet making machine mainly used to produce corrugated profiled tiles. This equipment adopts advanced technology and structural design, has the characteristics of high efficiency, stability and easy operation, and has become one of the indispensable and important equipment in the field of modern construction.

Metal Roof Sheet Making Machine

Specification

No. |

Number |

Metal Roof Sheet Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Application

1. Construction industry: used to produce tiles of various specifications, such as cement tiles, color steel tiles, etc., to provide high-quality roofing materials for houses, factories and other buildings.

2. Industrial field: It can be used to produce various metal plates, pipes and other industrial parts to meet the needs of industrial production.

3. Agricultural field: Used to produce skeletons, supports and other materials for agricultural greenhouses, providing a solid material foundation for agricultural production.

Notice

1. Safe operation: Before operating the equipment, you must be familiar with the structure, performance and safe operating procedures of the equipment to ensure personal safety and equipment safety.

2. Equipment maintenance: Carry out regular maintenance and care on the equipment, check whether the performance indicators of the equipment are normal, and discover and deal with potential problems in a timely manner.

3. Reasonable material selection: Select appropriate tile materials and specifications according to production needs to ensure product quality and production efficiency.

4. Comply with regulations: During the production process, equipment usage regulations and operating procedures must be strictly observed to avoid equipment damage or safety accidents caused by illegal operations.