Products

Machine For Corrugated Roof Sheets

Machine For Corrugated Roof Sheets

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Machine For Corrugated Roof Sheets

Machine For Corrugated Roof Sheets

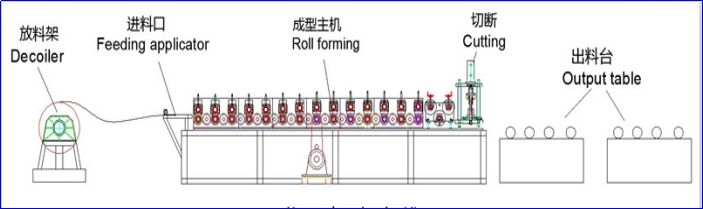

The machine for corrugated roof sheets is a mechanical equipment widely used in the industrial field. It is mainly used to press metal sheets into various shapes to meet the needs of different projects and product manufacturing.

Machine For Corrugated Roof Sheets

Specification

No. |

Number |

Machine For Corrugated Roof Sheets |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. Easy to operate: The machine for corrugated roof sheets adopts a humanized operation interface and intelligent control system, making the operation easier and faster, and reducing the labor intensity of workers.

2. Easy maintenance: The machine for corrugated roof sheets has a reasonable structure design and is easy to maintain and maintain, extending the service life of the equipment.

3. High cost performance: Although the machine for corrugated roof sheets is superior to similar products in terms of performance and quality, its price is relatively reasonable and has a high cost performance, saving investment costs for enterprises.

Feature

1. High efficiency: The machine for corrugated roof sheets adopts advanced transmission system and high-speed motor, which greatly improves production efficiency, greatly shortens the production cycle, and improves the competitiveness of the enterprise.

2. High precision: The machine for corrugated roof sheets is equipped with a high-precision control system and forming mold to ensure that the tiles produced are accurate in size and beautiful in shape, meeting the high requirements of modern architecture for tile quality.

3. Multi-function: The machine for corrugated roof sheets can produce tiles of various specifications, such as corrugated tiles, flat tiles, trapezoidal tiles, etc., to meet the needs of different architectural styles.

4. Environmental protection and energy saving: This machine for corrugated roof sheets adopts advanced energy-saving technology to reduce energy consumption, reduce environmental pollution, and is in line with the development trend of green and environmental protection.