Products

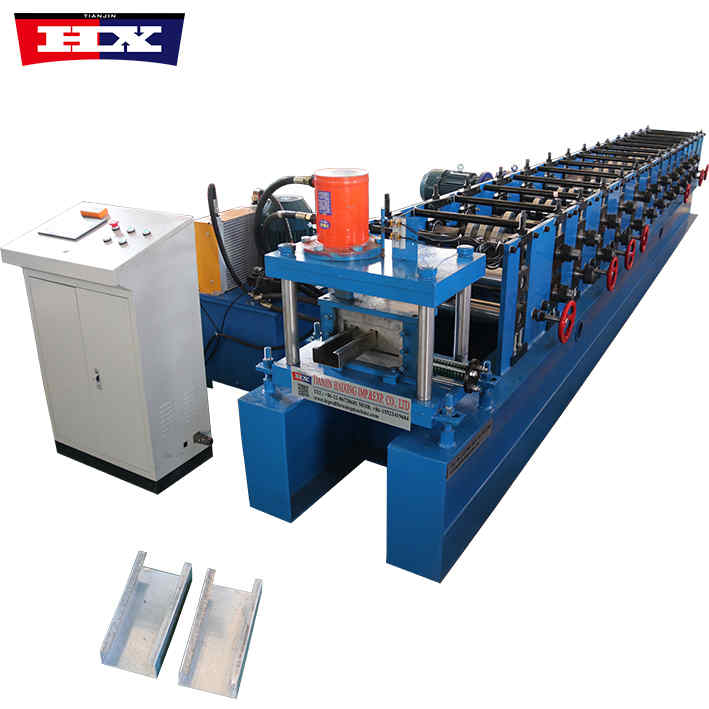

C Purlin Making Machine

C Purlin Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

C Purlin Making Machine

C Purlin Making Machine

C Purlin Making Machine

Specification

No. |

Number |

C Purlin Making Machine |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

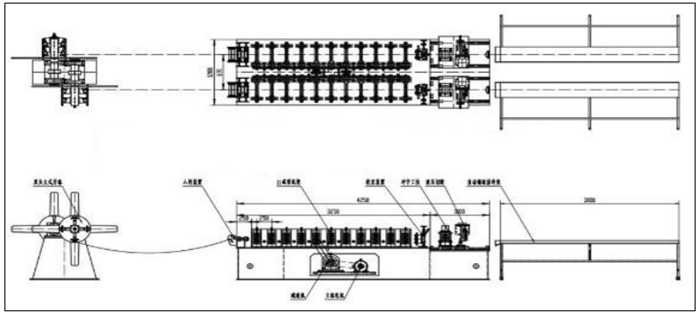

| 5. | Dimensions | 8*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

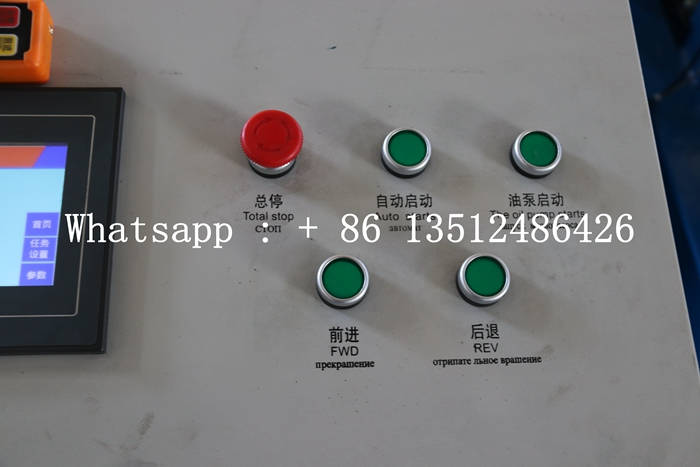

| 13. | Control system | PLC control ( Delta ) |

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 15 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. High efficiency: It can quickly and accurately complete purlin processing of various shapes and improve production efficiency.

2. High precision: Using advanced CNC technology, high-precision processing can be achieved.

3. Diversification: Purlins of various shapes and specifications can be processed to meet different building needs.

4. Automation: Use automated control systems to reduce manual intervention and improve production safety and product quality.

How To Choose

1. Functionality: You should choose a purlin machine that can meet your needs, such as processing speed, processing accuracy, processing range, etc.

2. Durability: Choosing a purlin machine with reliable quality and stable performance can ensure the stability and safety of long-term use.

3. Price: Choosing a purlin machine with reasonable price and high cost performance can ensure your own economic benefits.

So you can choose us, we can meet your all reqiurement.