Products

Purlin Roll Forming Machine

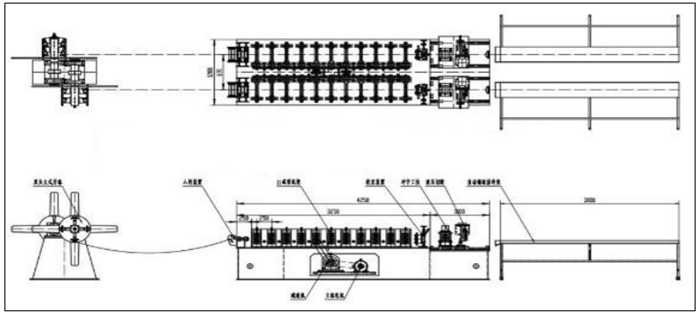

Purlin Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

Purlin Roll Forming Machine

Purlin Roll Forming Machine

Steel structure buildings are widely used in modern society. Their advantages include high strength, good stability, and short construction period. As one of the important components of steel structure buildings, the efficient production technology of C purlin roll forming machine is crucial to ensuring building quality and improving project progress.

The C purlin roll forming machine is an automated equipment mainly used to process and manufacture C-shaped steel purlins of various specifications. It adopts advanced CNC technology and intelligent control system to complete processing tasks quickly and accurately, greatly improving production efficiency and product quality.

The steel structure C purlin roll forming machine can efficiently produce C-shaped steel purlins of various specifications and sizes through advanced technology and intelligent control systems to meet the needs of different projects. It plays an important role in improving construction efficiency, ensuring project quality and saving labor costs. With the continuous development of science and technology, we believe that C-shaped steel purlins will have more innovation and applications, bringing a better future to the steel structure construction industry.

Purlin Roll Forming Machine

Advantages

1. The C purlin roll forming machine is highly flexible. By adjusting machine parameters and mold design, Z-shaped steel purlins of various specifications and sizes can be produced to meet different project needs. This facilitates the needs of different shapes and structures during building construction.

2. The production process of C purlin roll forming machine is relatively simple and easy to operate. You only need to feed the raw materials into the machine and set the relevant parameters, and the machine can automatically perform cutting, punching, bending and other processing processes, greatly reducing labor input and processing time, and at the same time reducing errors caused by human operations.

3. The C purlin roll forming machine also has high precision and stability. The cooperation of sensors and control systems can achieve precise monitoring and control of processing quality, ensuring that each C purlin roll forming machine produced meets the design requirements. At the same time, the structural stability of the machine itself and the precision control of cutting, punching and other processes can also ensure the consistency and stability of the product.