Products

Glazed Roof Tiles Making Machine For Sale

Glazed Roof Tiles Making Machine For Sale

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

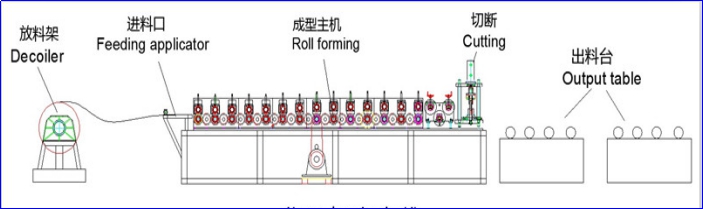

Glazed Roof Tiles Making Machine For Sale

Glazed Roof Tiles Making Machine For Sale

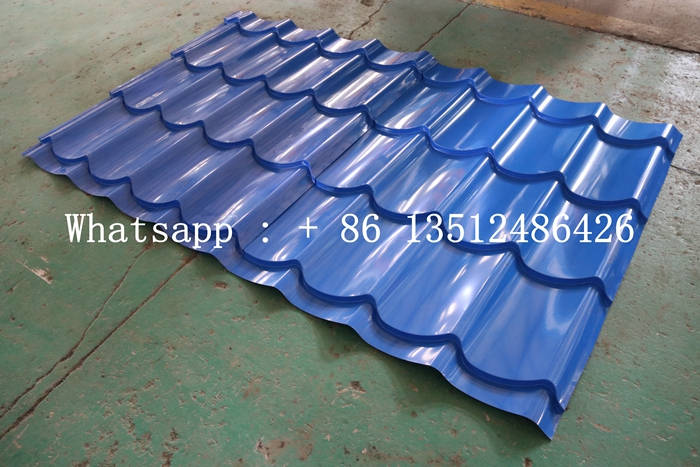

1. High efficiency: Roofing sheet making machine adopts advanced transmission system and molding technology, which greatly improves the production efficiency of the equipment.

2. Stable: The roofing sheet making machine has a solid structure, stable operation, and can work continuously for a long time to meet the needs of large-scale production.

3. Easy to operate: The control system adopts PLC control, which is easy to operate and maintain, and reduces labor costs.

4. Diversification: Roofing sheet making machine can produce corrugated tiles of various specifications to meet the needs of different architectural styles.

Glazed Roof Tiles Making Machine For Sale

Specification

No. |

Number |

Glazed Roof Tiles Making Machine For Sale |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 11 |

| 19. | Size | 6000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Notice

1. Before using the roofing sheet making machine, staff should be familiar with the structure, performance and operation methods of the equipment to ensure the safe operation of the equipment.

2. Before starting the roofing sheet making machine, check whether all components are intact and whether the oil level of the transmission system and hydraulic system is normal to ensure that the equipment is in good working condition.

3. During the production process, the operating status of the equipment should be checked regularly. If any abnormality is found, the machine should be shut down for inspection in time to avoid equipment damage or impact on product quality.

4. During the operation of the roofing sheet making machine, it is prohibited to adjust the spacing and angle of the pressing rollers at will to avoid damaging the equipment or affecting product quality.

5. After production, the residue inside the equipment should be cleaned in time to keep the equipment clean and dry to prevent the equipment from rusting or being damaged.