Products

Glazed Roofing Sheet Machine

Glazed Roofing Sheet Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Glazed Roofing Sheet Machine

Glazed Roofing Sheet Machine

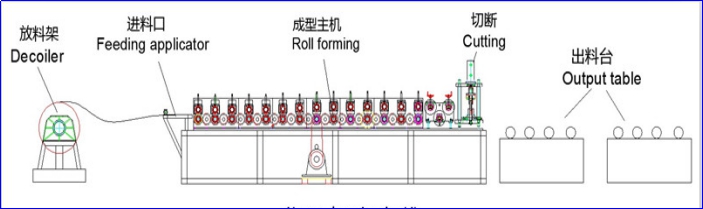

The glazed roofing sheet machine is divided into three parts, the roller forming part, the pressing part and the cutter part.

1. The roller forming part is driven by a motor, and the chain drives each roller to rotate.

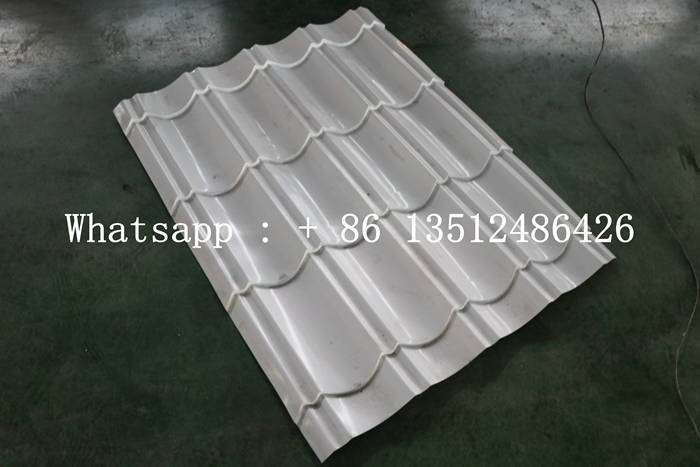

2. In the pressing part, the hydraulic cylinder drives the mold to move up and down, which can press the color steel into many sections, shaped like glazed tiles.

3. The cutting knife part is driven by a hydraulic cylinder to move up and down, which can cut off colored steel tiles.

The production process of the iron glazed metal roof wall panel roll forming machine is as follows: the colored steel plate enters the roller forming part. After forming, it goes to the pressing part and is pressed into equidistant sections. The cutter is responsible for cutting to a fixed length.

Glazed Roofing Sheet Machine

Specification

No. |

Number |

Glazed Roofing Sheet Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 9 |

| 19. | Size | 5000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Instructions

1. Start-up preparation

Before using the tile press computer, you need to make the following preparations:

1. Check whether the equipment is in normal working condition.

2. Check whether the tile mold is installed correctly to avoid mechanical failure caused by installation errors.

3. Check whether the device is connected to the correct power line, and check whether the power switch is turned off.

4. Check whether the lubricating oil is sufficient to ensure that the equipment operates smoothly during work.

2. Operation steps

1. Turn on the power of the equipment and start the computer control system.

2. Place the tiles to be produced in the mold, and adjust the mold to ensure that the angle and size of the mold meet the requirements.

3. Set production parameters in the computer control system, including tile length, width, thickness, production speed, etc.

4. Press the start button on the machine, and the equipment starts to work automatically to process and produce tiles.

5. During the production process, it is necessary to constantly check the operation of the equipment to ensure the normal operation of the equipment.

6. After production is completed, turn off the power of the equipment and clean and maintain the equipment.

3. Maintenance

1. Regularly check the electronic control system and mechanical transmission components of the equipment, and repair and replace them if necessary.

2. Change the lubricating oil in the equipment regularly to keep the equipment in good operating condition.

3. Clean the processing chips and residual tiles of the equipment to ensure the processing accuracy and work efficiency of the equipment.

4. Regularly maintain and upgrade the computer control system of the equipment to ensure the stability and work efficiency of the equipment.

In short, the tile press computer is one of the indispensable equipment in the current building materials production process. When using it, you need to pay attention to the above operating steps and maintenance measures to ensure the efficient operation of the equipment and production quality.