Products

Steel Coil Uncoiler

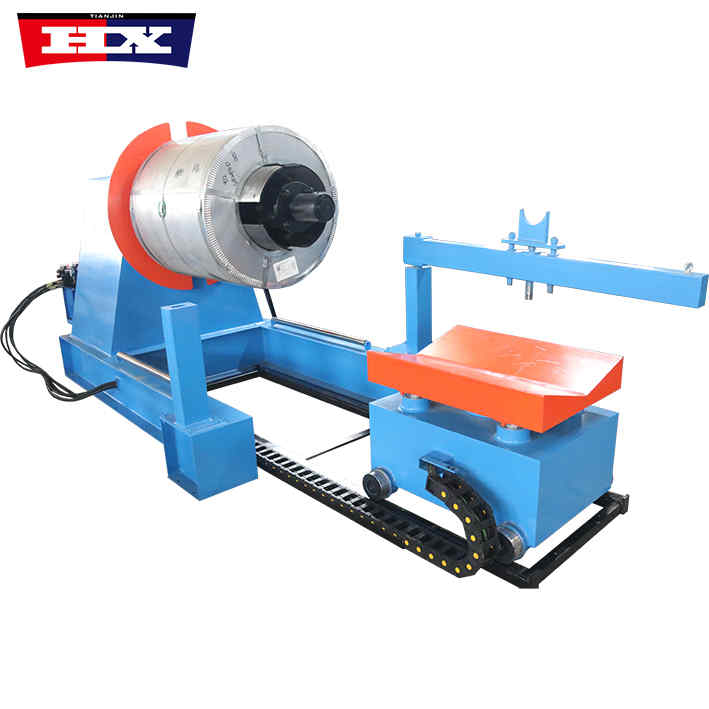

Steel Coil Uncoiler

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Steel Coil Uncoiler

Steel Coil Uncoiler

Steel coil uncoiler is a mechanical equipment used for unwinding coil materials. It is mainly used for uncoiling metal, plastic, rubber and other coil materials to facilitate subsequent processing. The hydraulic decoiler is driven by a hydraulic system and has the advantages of fast speed, high strength and high efficiency, and is widely used in various industrial fields.

Specification

No. |

Number |

Steel Coil Uncoiler |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 7 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Operation

1. Confirm the unwinding direction: After determining the unwinding direction, adjust the direction and position of the unwinding roller.

2. Roll material installation: Install the roll material on the unwinding roller, pay attention to the direction and position of the roll material to avoid deviation.

3. Adjust the distance of the unwinding roller: adjust the distance of the unwinding roller according to the width and diameter of the coil material. The distance on both sides of the unwinding roller needs to be adjusted appropriately to ensure that the roll material does not slip or get stuck.

4. Confirm the hydraulic system: Confirm that the status of the hydraulic system is normal, check whether the hydraulic pipelines are correctly connected, confirm the status of the pressure gauge, pressure regulating valve and relief valve, etc.

5. Start the hydraulic decoiler: Press the start button and control the hydraulic system through the joystick to run the decoiler.

6. Coil operation: When the coil starts running, check and adjust the position and tension of the coil in time to ensure smooth operation.

7. Shutdown operation: When it is necessary to stop the machine, first stop the movement of the coil material, turn off the hydraulic system, and then remove the coil material from the unwinding roller.