Products

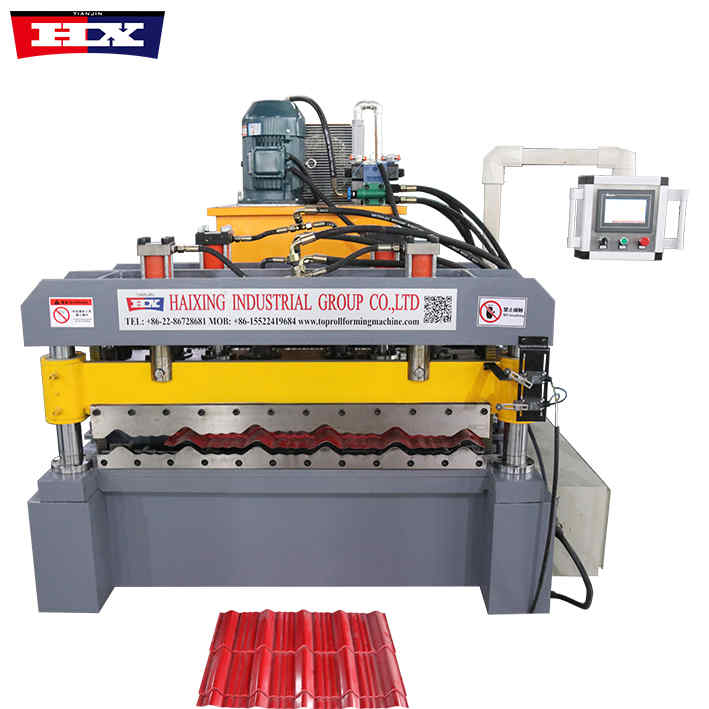

Step Tile Roll Forming Machine

Step Tile Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Step Tile Roll Forming Machine

Step Tile Roll Forming Machine

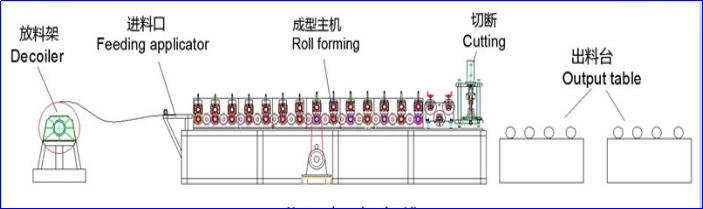

The step tile roll forming machine can produce roof panels with various appearances according to production needs, and. The products are widely used in the production of various industrial plants, private houses, warehouses and simple steel shed roofs and are beautiful and elegant. The machine is mainly composed of a feed introduction platform, a molding host, a molding and shearing device, a hydraulic station, and a computer control system. Optional configurations include ordinary unloading machine, hydraulic unloading machine, automatic chopping machine, etc.

Step Tile Roll Forming Machine

Specification

No. |

Number |

Step Tile Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Features

1. Efficient production: The corrugated rolling machine adopts an advanced hydraulic system, which makes the equipment more stable during high-speed operation and greatly improves production efficiency. At the same time, the equipment also has functions such as automatic feeding and automatic shearing, which further improves production efficiency.

2. Various specifications: The corrugated rolling machine can produce corrugated tiles of various specifications to meet different building needs. Users can adjust the equipment parameters according to actual needs to produce tiles that meet the requirements.

3. Easy to operate: The operation interface of the corrugated rolling machine is simple and clear, making it easy to use. At the same time, the equipment is also equipped with safety protection devices to ensure safety during operation.

4. Durable and stable: The corrugated rolling machine is made of high-quality materials and undergoes strict technological processes to ensure that the equipment has a long service life and stable performance.

Maintain

1. Keep the equipment clean: Clean the equipment regularly to remove oil and dust to ensure normal operation of the equipment.

2. Check the hydraulic system regularly: Check the oil level and quality of the hydraulic oil, and replace the hydraulic oil in time to ensure the stable operation of the hydraulic system.

3. Check the pressure roller regularly: Check the wear of the pressure roller. If the wear is serious, replace it in time to ensure the quality of the pressed tiles.

4. Regularly check the safety protection device: ensure the normal operation of the safety protection device, and repair or replace damaged parts in a timely manner.