Products

Corrugated Roll Forming Machine

Corrugated Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Roll Forming Machine

Corrugated Roll Forming Machine

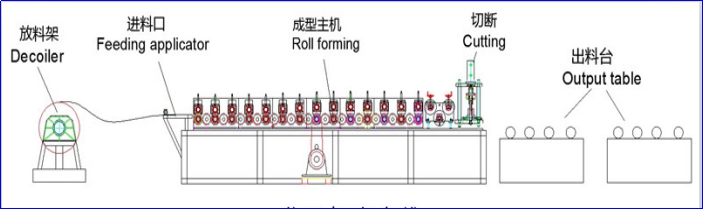

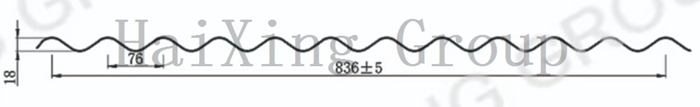

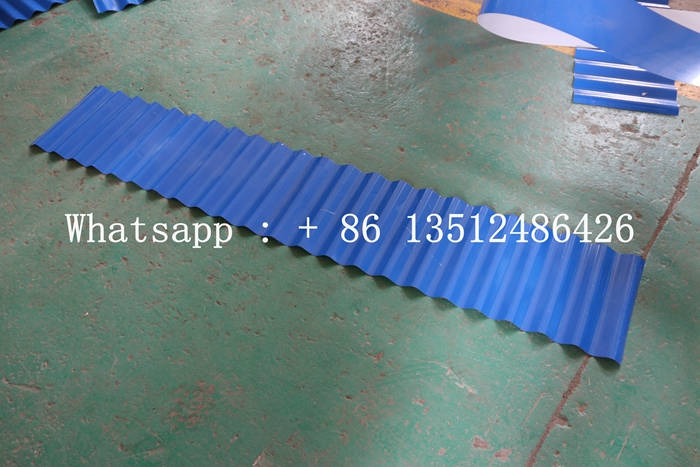

The corrugated roll forming machine consists of unloading, forming, and post-forming and cutting. The color plates produced have a smooth and beautiful appearance, uniform paint patterns, high strength, and durability. They are widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters, etc. House surface and walls.

1. Efficient, precise and stable production capacity.

2. Using a chain drive system, the tile pressing work can be completed quickly and accurately, greatly improving production efficiency.

3. It has a high degree of automation and intelligence, can realize automatic control and intelligent management, and reduces labor costs and labor intensity.

Corrugated Roll Forming Machine

Specification

No. |

Number |

Corrugated Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. By using a tile press, various types of tiles can be laid easily, such as colored steel tiles, etc. These tiles are machine pressed and shaped to ensure dimensional consistency and quality stability.

2. The tile press can achieve high-speed laying and improve construction efficiency and work efficiency. It can quickly complete the roof laying work, reducing labor and time costs.

3. Pressed tiles have high density and durability, and can be effectively waterproof, shockproof and windproof. This provides reliable protection for residential buildings and increases their service life.

4. Various types of tiles are available in rich colors and can be selected according to the design and style of the residential building, providing beautiful appearance and decorative effects.

Features

1. Efficient and stable: The corrugated roll forming machine adopts advanced transmission system and hydraulic system to ensure stable and efficient operation of the equipment. During the pressing process, the synergistic effect of the upper and lower pressing rollers allows the plate to be pressed in a short time, greatly improving production efficiency.

2. Easy to operate: The electronic control system of the equipment adopts humanized design and is easy to operate. Workers can start, stop, speed adjust and other operations of the equipment simply by pressing the buttons on the control panel.

3. Wide scope of application: The corrugated roll forming machine is suitable for producing corrugated tiles and can meet the needs of different construction projects. At the same time, the equipment also has high flexibility and can adjust the spacing and angle of the pressing rollers according to production needs to adapt to the pressing of plates of different specifications.

4. Easy maintenance: The equipment has a reasonable structural design and is easy to maintain and maintain. The key components of the transmission system and hydraulic system are made of high-quality materials, which are wear-resistant and durable, reducing maintenance costs.