Products

Corrugated Roofing Sheet Forming Machine

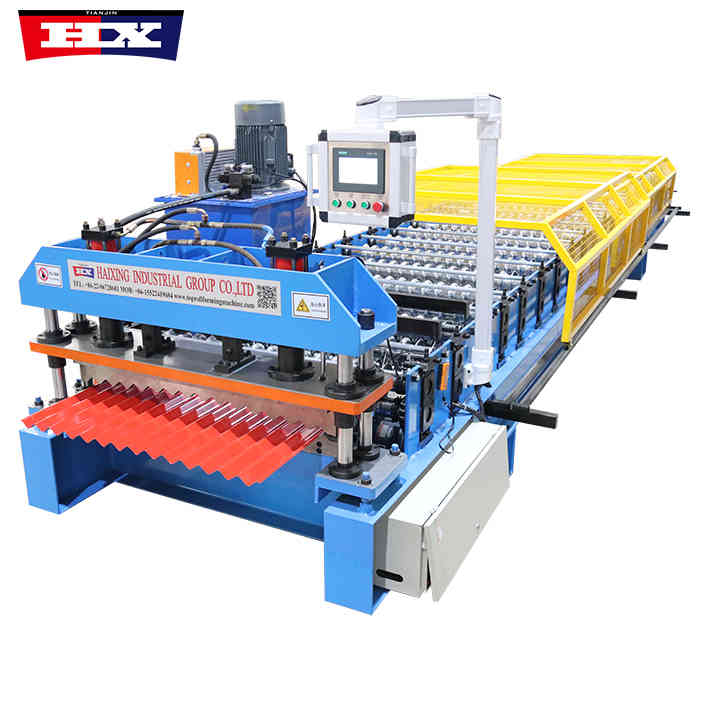

Corrugated Roofing Sheet Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Roofing Sheet Forming Machine

Corrugated Roofing Sheet Forming Machine

Specification

No. |

Number |

Corrugated Roofing Sheet Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Machine Advantages

1. High-efficiency production: greatly improves production efficiency and reduces production time.

2. Quality assurance: Advanced technology and craftsmanship ensure the quality of the tiles, giving them good durability and stability.

3. Diversified choices: Tiles of various shapes and specifications can be produced to meet various architectural design needs.

4. Cost saving: High-efficiency production methods reduce costs and save materials and human resources for users.

5. Easy to operate: The design is user-friendly, the operation is simple and easy to understand, and no professional skills are required, which reduces the training cost of operators.

6. Strong adaptability: suitable for various roof types and building structures, with high versatility.

7. Safe and reliable: Good safety performance ensures the safety of operators and reduces the risk of accidents.

Application

1. Construction field: The corrugated roofing sheet forming machine can be used to produce corrugated sheets of various shapes and specifications, such as roof panels, wall panels, etc., and is widely used in industrial plants, warehouses, cold storages, residential buildings and other construction fields.

2. Decorative field: The corrugated sheets produced by the corrugated roofing sheet forming machine have good decorative effects and can be used for indoor and outdoor walls, ceilings, partitions and other decorative projects to improve the beauty and practicality of the overall space.

3. Transportation field: The corrugated sheets produced by the corrugated roofing sheet forming machine can also be used in transportation facilities, such as highway guardrails, railway soundproof walls, etc., with good durability and stability.

4. Home appliance field: The corrugated roofing sheet forming machine can also be used to produce shells and parts of home appliances, such as refrigerators, air conditioners, washing machines, etc., and has good anti-rust and anti-corrosion properties.