Products

Corrugated Sheet Rolling Machine

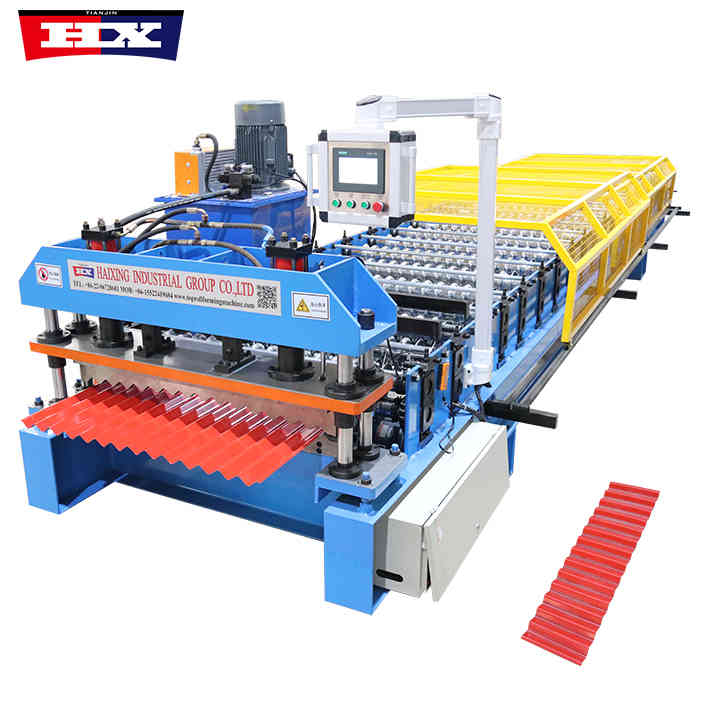

Corrugated Sheet Rolling Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Sheet Rolling Machine

Corrugated Sheet Rolling Machine

Specification

No. |

Number |

Corrugated Sheet Rolling Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Effect

1. The function of tile press

The tile press is mainly used to process metal tiles and can shape and cut metal tiles. Its functions include:

1). Formed metal tiles: Through the pressure and mold of the tile press, flat metal tiles can be processed into tiles with specific shapes such as arcs or waves to suit different building needs.

2). Cutting metal tiles: The tile press can also cut metal tiles as needed to adapt to various tile installation and use needs.

2. Working principle of tile press

The working principle of the tile press is to use mechanical pressure to process metal tiles. The specific steps are as follows:

1). Select the metal tile material and place it on the feeding drum of the tile press.

2). The metal tiles are shaped and cut through the rollers and molds of the tile press to obtain the required tile shape and size.

3). The operator adjusts the rollers and molds of the tile press according to needs to achieve different metal tile processing.

3. Application fields of tile press

Tile presses are widely used in construction, agriculture, industry and other fields. The main application scenarios include:

1). Construction field: The tile press can process metal tiles of different shapes and is suitable for various types of roofs and walls, such as roof tiles, wall panels, etc.

2). Agricultural field: The tile press can be used to process agricultural facilities, such as garden sheds, livestock sheds, etc., to meet different agricultural production needs.

3). Industrial field: The tile press can be used to process various types of components, containers, pipes and other metal materials for the production of different industrial products.