Products

Decoiler Sheet Metal

Decoiler Sheet Metal

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Decoiler Sheet Metal

Decoiler Sheet Metal

Product structure: It mainly includes coil support device, unwinding head, flattening device, clamping device, feeding device and control system. Among them, the coil support device is used to support the coil, the unwinding head is used to peel off the coil, the flattening device is used to flatten the coil, the clamping device is used to clamp the material, and the feeding device is used to send the material to the subsequent processing equipment, and the control system is used to control the operation of the entire equipment.

Working principle:

The decoiler sheet metal usually consists of two upper and lower rollers and two side plates. The coil is placed between the upper and lower rollers. Driven by the rollers, the coil is brought to the cutting position. At the same time, the role of the side plates is to maintain the stability of the coil.

When the de coiler is working, a control system will control the cutting length and speed of the coil. Different cutters are required for cutting different coils to ensure the best shearing effect.

Specification

No. |

Number |

Decoiler Sheet Metal |

| 1. |

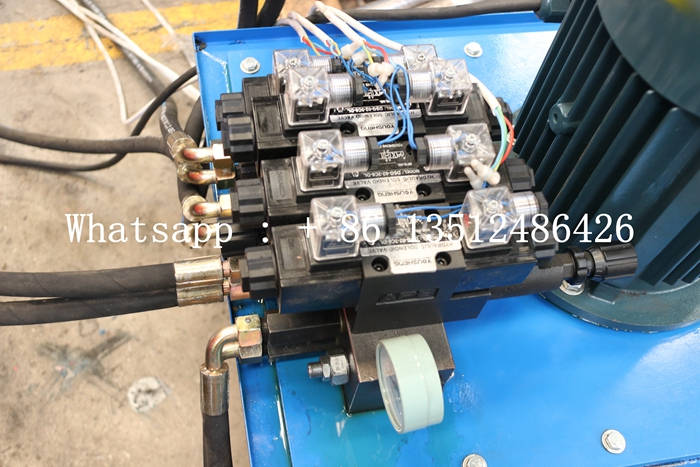

Hydraulic pump station |

4kw (Electromagnetic valves) |

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 10 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Advantages

1. Save labor and time costs

In the traditional uncoiling method, manual labor is required to peel off the coiled material layer by layer to complete the uncoiling process. This method is time-consuming, laborious, and uneconomical. The rolls can be easily layered using an uncoiler, which greatly reduces the manpower required and the time cost.

2. Improve production efficiency and quality

The use of the decoiler sheet metal can quickly and accurately layer the coils, greatly improving production efficiency. In addition, the use of decoilers can also effectively reduce error rates and improve product quality. Using an uncoiler can layer the coils more evenly, reducing errors and waste in production.

3. More secure and reliable

The use of decoiler sheet metal can make operations safer and more reliable, allowing operators to reduce risks during operations, thus improving production safety.

4. Wide range of application

Decoiler sheet metal can be used in many different industries, such as metal products, chemical products, construction materials, and many other industries. Regardless of the type of material, it can be uncoiled by using an uncoiler.