Products

Metal Roofing Sheet Roll Forming Machine

Metal Roofing Sheet Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Metal Roofing Sheet Roll Forming Machine

Metal Roofing Sheet Roll Forming Machine

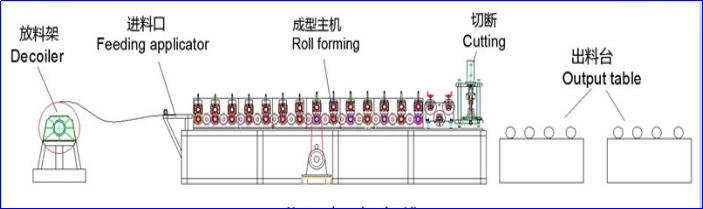

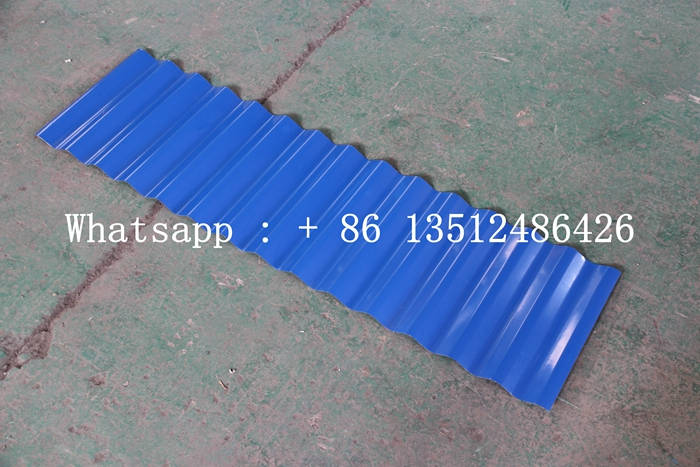

The metal roofing sheet roll forming machine is an efficient and precise metal processing equipment that is widely used in construction, decoration, transportation, home appliances and other fields. Its main function is to press metal sheets into corrugated sheets of various shapes to meet the needs of metal corrugated sheets in different fields.

Metal Roofing Sheet Roll Forming Machine

Specification

No. |

Number |

Metal Roofing Sheet Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 13 |

| 19. | Size | 6500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

How To Operate

1. Machine debugging

1). Turn on the power of the machine and check whether all parts are normal.

2). Configure a regulating valve to control the hydraulic oil flow rate.

3). Stabilize the machine speed to ensure smooth operation during plate pressing.

4). Collect appearance and other parameter information, turn on the adjustment gear, and conduct debugging.

2. Plate positioning

1). Define the size and length of the plate and cut it.

2). Set the plate length and number of layers on the tile press.

3). Position the plate and adjust the angle of the inclined plate.

4). Set the pressing force of the tile press and test the board in advance.

3. Suppression operation

1). Store board size and length.

2). Place the board on the tile press and adjust the position carefully.

3). Start pressing to gradually deform the plate according to the preset shape.

4). Wait for the machine operation to complete and check whether the plate meets the requirements.

5). Take out the board, clean up the remaining material, and repeat the above steps.