Products

Metal Stud Roll Former Machine

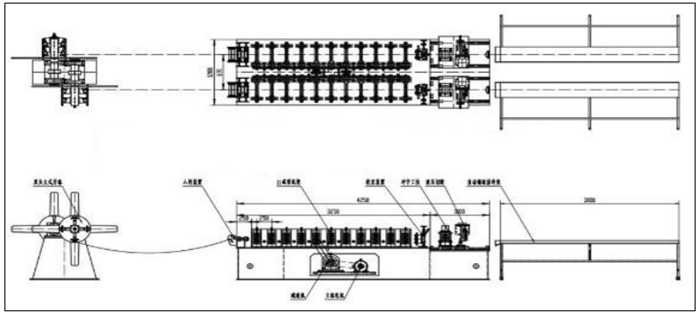

Metal Stud Roll Former Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Metal Stud Roll Former Machine

Metal Stud Roll Former Machine

Application

1. Partition walls: Light steel keels are suitable for partition walls in offices, residential and commercial spaces, and can flexibly divide space according to needs

2. Ceiling and wall decoration: Light steel keels can be used for ceiling and wall decoration, creating a modern and unique design effect.

3. Roof and roof trusses: Light steel keels can also be used in the construction of roofs and roof trusses to support the roof structure.

4. Indoor furniture: In the production of indoor furniture, such as wardrobes, bookshelves, etc., light steel keels can also play an important role.

Metal Stud Roll Former Machine

Specification

No. |

Number |

Metal Stud Roll Former Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6.5*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.5t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 12 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. Lightweight and high strength: Light steel keels are made of steel and have high strength, but are relatively light in weight. This allows the use of lightweight steel keels in buildings to reduce structural loads, thereby reducing the overall weight of the building.

2. Convenient construction: Light steel keels usually adopt standardized sizes and can be prefabricated into components, making the construction process faster and more convenient. It can be cut and connected according to design needs to adapt to different structural requirements.

3. Corrosion resistance: Steel itself has good corrosion resistance, so light steel keels can maintain stable performance in humid environments, reducing the need for maintenance and replacement.

4. Flexibility: Light steel keels can be designed and adjusted as needed, and are suitable for a variety of different architectural styles and uses, such as residential, commercial, and industrial buildings.

5. Environmental protection: Light steel keels are usually made of recycled materials, which is conducive to the sustainable use of resources. At the same time, its lightweight design can also reduce the building's consumption of natural resources.