Products

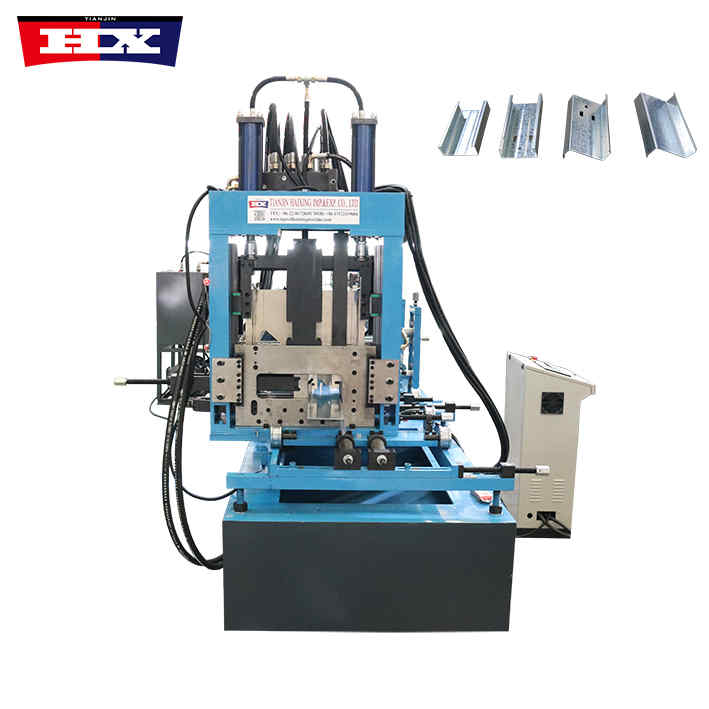

Purlin Machine For Sale

Purlin Machine For Sale

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

Purlin Machine For Sale

Purlin Machine For Sale

The fully automatic C/Z purlin machine for sale changing machine uses the same set of equipment to produce various specifications of C/Z purlins through automatic stepless adjustment. There is no need to replace the forming roller when changing specifications. The production process adopts automatic control mode, which can automatically punch, cut and form according to the input purlin length, longitudinal hole spacing, quantity and other parameters.

Purlin Machine For Sale

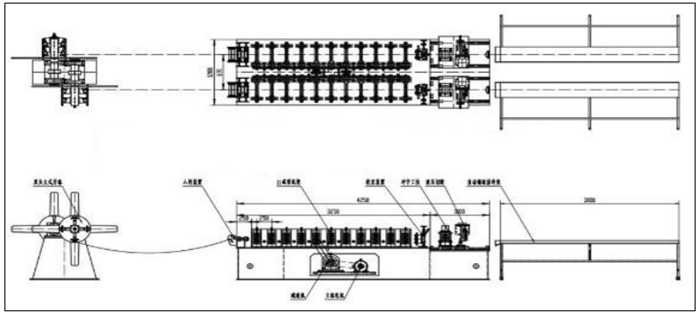

Specification

No. |

Number |

Purlin Machine For Sale |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

| 5. | Dimensions | 9*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

| 13. | Control system | PLC control ( Delta ) |

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 16 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

Operation

1. Place the material in the feeding position of the machine. Make sure the material is secure and flat.

2. Adjust the machine parameters, including the position of the cutter, the pressure of the cutter, and the cutting speed. Adjust these parameters reasonably according to the type and requirements of the material.

3. Turn on the power of the machine and start the host. Select the corresponding processing program according to the instructions on the machine's operation interface or operation panel.

4. Press the start button to start the machine's automatic processing process. During the processing process, the working status of the machine can be monitored through the instructions on the monitoring screen or operating interface.

5. During the processing, if any abnormality is found (such as material jamming or tool damage, etc.), the machine can be stopped through the emergency stop button and the abnormality should be handled in a timely manner.

6. After the processing is completed, turn off the power and host of the machine, and clean up the waste materials and chips generated during the processing.