Products

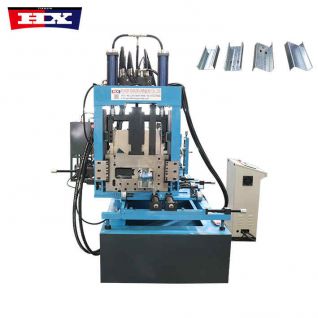

Automatic CZ Purlin Roll Forming Machine

Automatic CZ Purlin Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 1.5-3mm

Produce Speed : 8-10m/min

Port : Tianjin

Automatic CZ Purlin Roll Forming Machine

Automatic CZ Purlin Roll Forming Machine

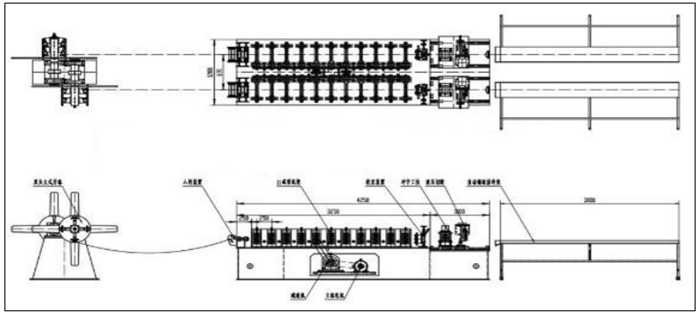

The CZ purlin machine is a single-roll forming unit with one set of rolls that can produce CZ-shaped purlin products of various specifications. The machine mainly consists of a passive loading rack, leveling device, punching device, post-forming cutting device, hydraulic station, computer control system, etc.

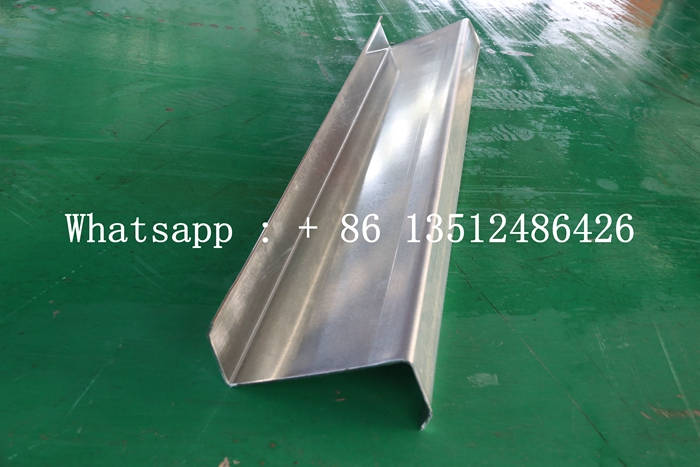

The finished CZ purlin rolled by this CZ purlin machine has good bending and compression resistance, good straightness, fully automatic fixed-length cutting, automatic punching, high degree of automation, and fast and convenient installation.

The product can be used as the main stress-bearing structure of large and medium-sized industrial and civil buildings, such as roof load-bearing loads and wall supports of factories, warehouses, locomotive garages, hangars, exhibition halls, theaters, sports venues, and market garden sheds.

Automatic CZ Purlin Roll Forming Machine

Specification

No. |

Number |

Automatic CZ Purlin Roll Forming Machine |

| 1. | Suitable to process |

PPGI/PPGL/GI/GL/Carbon |

| 2. | Side panel of machine | 22mm |

| 3. | Rolling materials | Gcr15 Steel Quenched treatment HRC 58-62℃ |

| 4 | Main structure | Square steel frame 450H steel |

| 5. | Dimensions | 9*1.5*1.7m |

| 6. | Materials of cutting blade |

Cr12,Quenched treatment HRC 58-62℃ |

| 7. | Weight | About 6.5t |

| 8. | Produce speed | 8-10m/min |

| 9. | Engine power | 11Kw |

| 10. | Pump station engine | 4kw |

| 11. | Thickness of plate | 1.5-3mm |

| 12. | Cutting way | Grinding tool twisted |

| 13. | Control system | PLC control ( Delta ) |

| 14. | Diameter of roller | Φ80mm |

| 15. | Drive method | Chain ( 2 inch ) |

| 16. | Rows | 16 |

| 17. | Length tolerance | ±2mm |

| 18. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. The CZ interchangeable purlin machine can produce two different types of purlins. Among them, the C-type purlins are very stable in texture and have excellent pressure resistance. Even if they bear heavy external force, the straightness of the purlins will not be affected. Degree; Z-shaped purlins not only have strong pressure resistance, but can also be constructed and installed in the opposite direction to adapt to different needs;

2. The drive of the CZ interchangeable purlin machine has also been improved. It is equipped with a frequency conversion control that is not available in general purlin machines. This control system can more accurately position the products in the production line. Specifically, it can not only control the production speed of the purlins , the specifications of the purlins can also be precisely controlled to ensure different precision requirements of the purlins;

3. The biggest feature of the CZ interchangeable purlin machine is that it can mix the manufacturing processes of C-type and Z-type purlins. It can produce purlins with both the advantages of C-type and Z-type according to the different needs of users, which can greatly reduce the number of customers. purchase cost;

4. The conversion between C-type purlins and Z-type purlins is also very convenient, and the production of purlins is highly efficient and fast.