Products

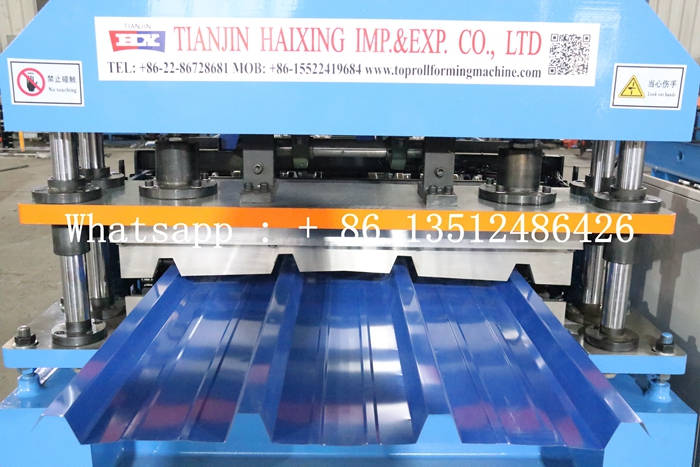

Roof Sheet Machine For Sale

Roof Sheet Machine For Sale

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

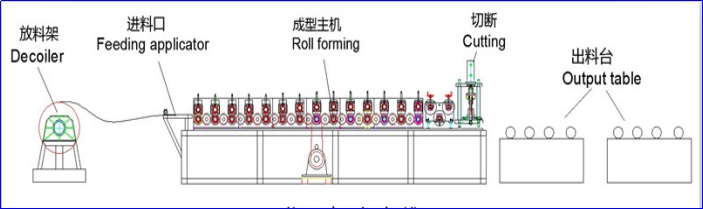

Roof Sheet Machine For Sale

Roof Sheet Machine For Sale

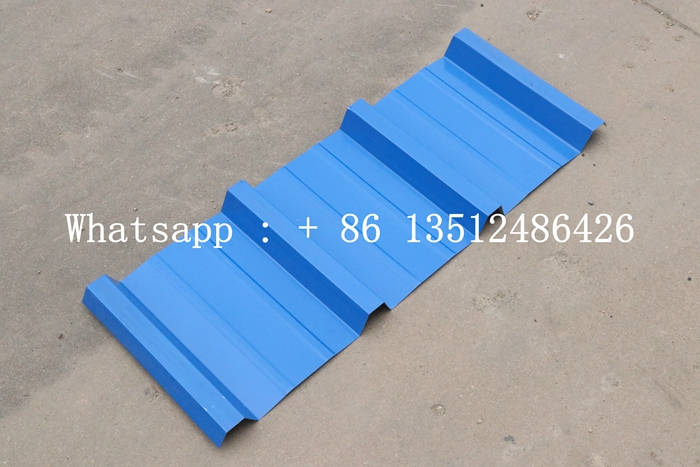

1. Construction field: The roof sheet machine for sale is mainly used to produce trapezoidal tiles for various constructions, such as flat to slope, roof waterproofing, etc.

2. Garden landscape: The roof sheet machine for sale can also be used to produce trapezoidal tiles for various garden landscapes, such as flower stands, walls, pavilions, etc.

3. Other fields: such as highways, railways, water conservancy and other infrastructure construction also need to use trapezoidal tile forming machines.

Roof Sheet Machine For Sale

Specification

No. |

Number |

Roof Sheet Machine For Sale |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 18 |

| 19. | Size | 9000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Notice

1. Comply with safety regulations: When operating the trapezoidal roof roll forming machine, be sure to abide by safety regulations and wear safety protective equipment to ensure personnel safety.

2. Regular maintenance: Perform regular maintenance on the equipment, check the wear and tear of various parts of the equipment, and replace damaged parts in a timely manner to ensure the normal operation of the equipment.

3. Pay attention to the quality of raw materials: Use high-quality raw materials for production to ensure the quality and performance of the tiles.

4. Reasonably adjust parameters: According to production needs and raw material characteristics, reasonably adjust the operating parameters of the equipment to obtain the best production results.