Products

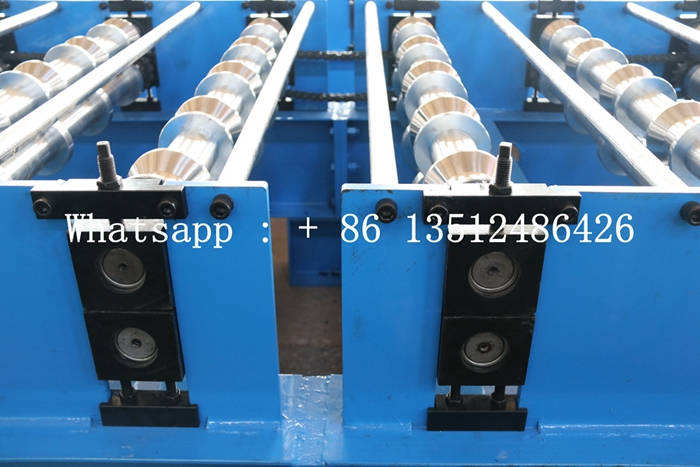

Sheet Trapezoidal Roof Roll Forming Machine

Sheet Trapezoidal Roof Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Sheet Trapezoidal Roof Roll Forming Machine

Sheet Trapezoidal Roof Roll Forming Machine

Features:

1. The sheet trapezoidal roof roll forming machine has efficient production capacity. It uses advanced technology and design to quickly produce large quantities of tiles in a short period of time. This makes it one of the indispensable production equipment in the construction industry and manufacturing industry.

2. The sheet trapezoidal roof roll forming machine has the characteristics of high precision and high stability. It produces high-quality tiles with each tile being the same size and shape. This makes it widely used in the construction and manufacturing fields, as it can meet a variety of different production needs.

3. The sheet trapezoidal roof roll forming machine is also easy to operate and maintain. It adopts a simple and easy-to-use operation interface and control method, making operation and maintenance more convenient and faster. At the same time, it also has low energy consumption and operating costs, making it an economical production equipment.

Sheet Trapezoidal Roof Roll Forming Machine

Specification

No. |

Number |

Sheet Trapezoidal Roof Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 15 |

| 19. | Size | 7500mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Advantages

1. High production efficiency: Sheet trapezoidal roof roll forming machine adopts automatic control, has high production efficiency and can produce multiple tiles at one time.

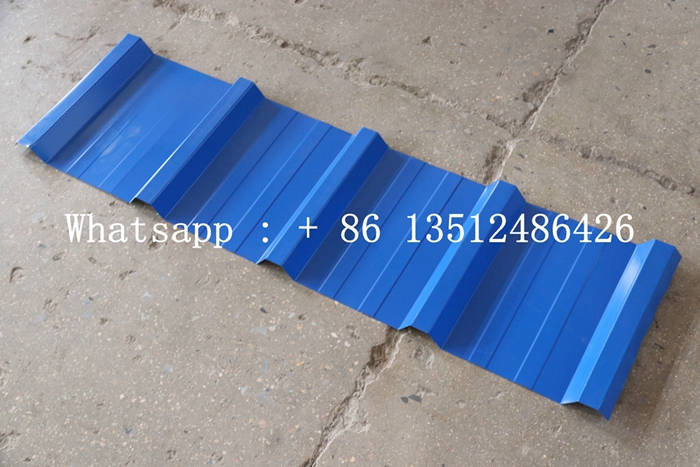

2. High-quality finished products: The tiles produced by sheet trapezoidal roof roll forming machine are of good quality and are beautiful, durable, and resistant to pressure.

3. Wide applicability: This sheet trapezoidal roof roll forming machine is suitable for the production of various building materials, such as cement tiles, concrete tiles, stone tiles, etc.

4. Low maintenance cost: The components used in sheet trapezoidal roof roll forming machine have been strictly tested and tested, and have good durability and maintainability.

5. Simple operation: The sheet trapezoidal roof roll forming machine is simple to operate, does not require too many technical personnel to operate, and can also achieve automated production.