Products

Trapezoidal Roof Sheet Making Machine

Trapezoidal Roof Sheet Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Roof Sheet Making Machine

Trapezoidal Roof Sheet Making Machine

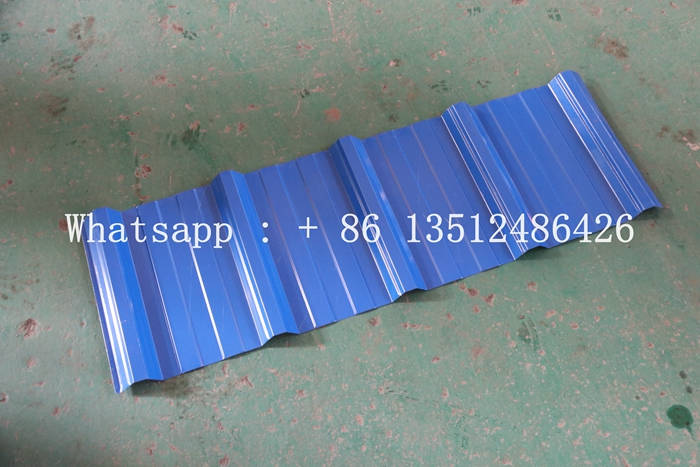

The trapezoidal roof sheet making machine is an efficient and practical metal sheet forming equipment, widely used in construction, decoration, metal products and other fields. This machine adopts advanced hydraulic technology and has the characteristics of high pressure, high precision, fast speed and long life. It can process metal plates of various specifications and shapes.

Trapezoidal Roof Sheet Making Machine

Specification

No. |

Number |

Trapezoidal Roof Sheet Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 11 |

| 19. | Size | 6000mm*1500mm*1600mm |

| 20. | Weight | 4000kg |

How To Use

1. Preparation

1). Check whether the machine and parts are intact. If damaged, repair or replace it in time.

2). Make sure the work area is tidy to prevent debris from interfering with the operation.

2. Set parameters

1).First select the desired tile type and specification, and adjust the machine's settings to suit that specification.

2).Adjust the speed and pressure of the tile press to ensure the quality and production efficiency of the tiles

3. Processing tiles

1). Place the metal material to be processed on the machine and ensure that the fixing force is appropriate

2). Start the tile press and let it process according to the preset parameters.

Maintain

1. Clean the work area and machine surface to remove dust and debris.

2. Pay attention to the lubrication situation and perform regular replacement and filling of lubricating oil according to the frequency of use.

3. Regularly check the wear of machine parts and replace them if necessary.

Application

1. Trapezoidal roof sheet making machine also play an important role in the manufacturing of electronic products, vehicles, mechanical equipment, furniture, home appliances and other industries.

2. In the manufacture of steel components, water tanks, lockers and other products, it is necessary to use a trapezoidal roof sheet making machine for forming processing.

3. The rapezoidal roof sheet making machine can also manufacture various punching, die-cutting and bending parts and other parts.