Products

Trapezoidal Roof Sheet Making Machine Price

Trapezoidal Roofing Sheet Manufacturing Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Roof Sheet Making Machine Price

Trapezoidal Roof Sheet Making Machine Price

The trapezoidal roof sheet making machine price is a common building material processing equipment, mainly used to process various types of roof tiles, wall panels, building sheets and other materials.

Trapezoidal Roof Sheet Making Machine Price

Specification

No. |

Number |

Trapezoidal Roof Sheet Making Machine Price |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

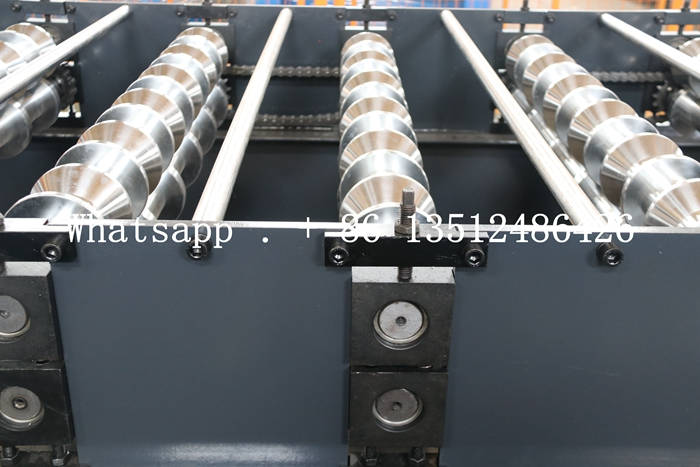

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 16 |

| 19. | Size | 8000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Precautions

1. Inspection before operation

Before each operation, the tile press must be carefully inspected, including the chassis, lower cutterhead, upper cutterhead, rollers, transmission mechanism and other major components. When inspecting, pay attention to whether the cables are worn, whether the cutting tape has fallen off, whether the lubrication is in place, etc., to ensure that no safety accidents are caused by problems with the equipment itself during operation.

2. Wear personal protective equipment

When using the tile press, the operator must wear appropriate personal protective equipment, such as safety shoes, earplugs, gloves, protective glasses, etc. These equipment can effectively block dangerous factors such as flying steel grinding chips and noise, and protect the safety of operators.

3. Stay awake during operation

When using the tile press, the operator must remain awake and must not operate while drinking, tired or in pain. In addition, during the operation, you must always stay focused, pay attention to the operating status of the equipment, and find and deal with problems in time.

4. Prevent electric shock

To ensure safe operation, operators must properly ground equipment. At the same time, it is necessary to ensure that electrical equipment such as plugs, sockets, and wires are in good condition during operation, and there must be no wear, breakage, metal contact, etc.

5. Use rated load

When using the tile press, it must be used according to the rated load of the equipment. Once overloaded, the equipment will be damaged and the operator's personal safety will be in danger. Therefore, the equipment must be used in accordance with regulations and overload use is strictly prohibited.

6. Stop and inspect before operation

When replacing the cutter, cutter holder, pressing roller and other equipment, you must first stop the machine and turn off the power. Repair and replacement operations can only be carried out after the machine has completely stopped.

7. It is prohibited to adjust at will

When using the tile press, operators are strictly prohibited from adjusting various mechanical components at will, including adjusting the tile press roller, lower and upper cutterheads, etc. All adjustments must be made by professionals.

8. Order after shutdown

After use, the tile press must be stopped and the power turned off. And clean the cutter, cutter holder, pressure tile and other parts in time to avoid danger during next use. At the same time, the machines should also be returned to their original positions to keep the workshop clean and orderly.