Products

Trapezoidal Sheet Metal Roofing Machine

Trapezoidal Sheet Metal Roofing Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

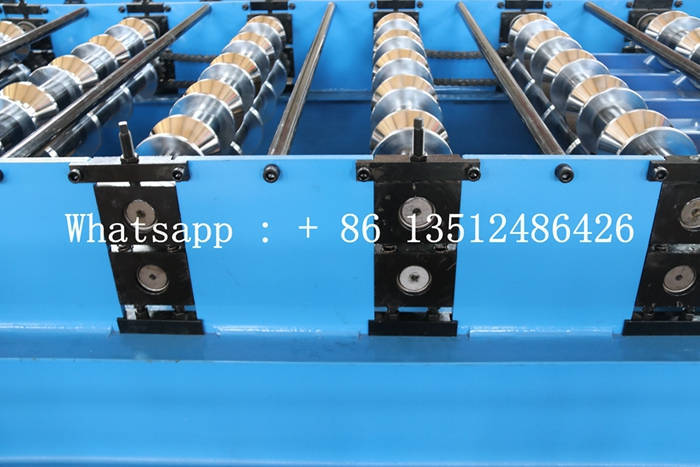

Trapezoidal Sheet Metal Roofing Machine

Trapezoidal Sheet Metal Roofing Machine

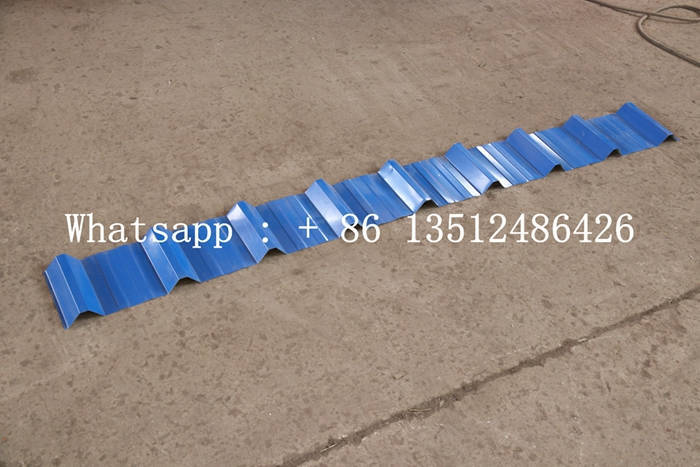

The main function of the trapezoidal sheet metal roofing machine is to press steel plates. The forming process of the steel plates pressed by the tile press consists of unloading, forming, and post-forming and cutting. The products produced after pressing have a smooth and beautiful appearance, uniform paint patterns, high strength, and durability. It is widely used in industrial and civil buildings, such as factories, warehouses, locomotive garages, aircraft hangars, gymnasiums, exhibition halls, theaters and other rooms and walls.

Trapezoidal Sheet Metal Roofing Machine

Specification

No. |

Number |

Trapezoidal Sheet Metal Roofing Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 15 |

| 19. | Size | 7500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. High efficiency: The trapezoidal sheet metal roofing machine adopts advanced pressing technology and can quickly complete the pressing work of metal tiles. Its efficient production capacity can greatly shorten the construction period and improve the progress of the project.

2. High precision: The trapezoidal sheet metal roofing machine is equipped with an advanced control system and precision molds to ensure that the pressed metal tiles have accurate dimensions and standardized shapes. This helps improve the overall quality of the building.

3. Easy to operate: The trapezoidal sheet metal roofing machine adopts a user-friendly design and is easy to operate. Even operators who are new to the equipment can quickly learn how to operate it.

4. Energy saving and environmental protection: The trapezoidal sheet metal roofing machine produces less noise and pollution during the pressing process and complies with national environmental protection standards. At the same time, it can effectively save energy and reduce production costs.