Products

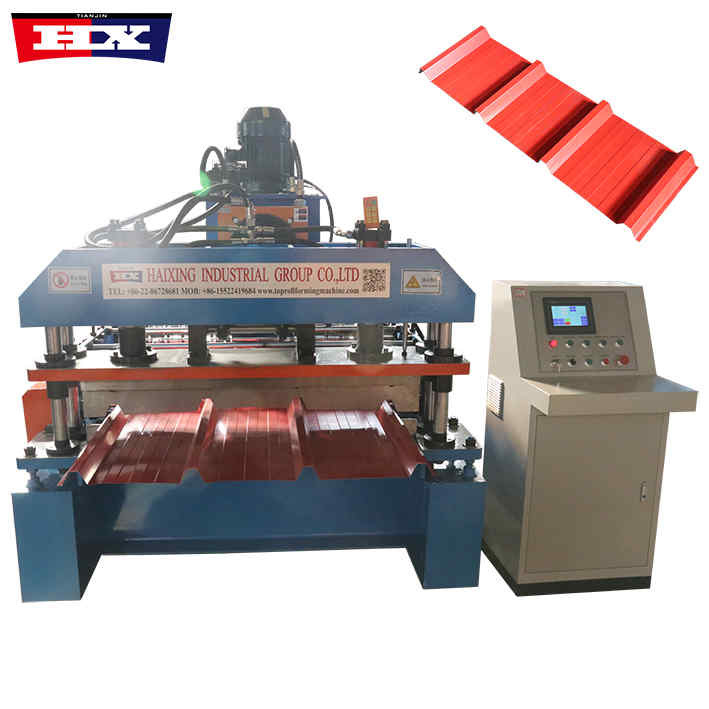

Trapezoidal Roofing Sheet Manufacturing Machine

Trapezoidal Roofing Sheet Manufacturing Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

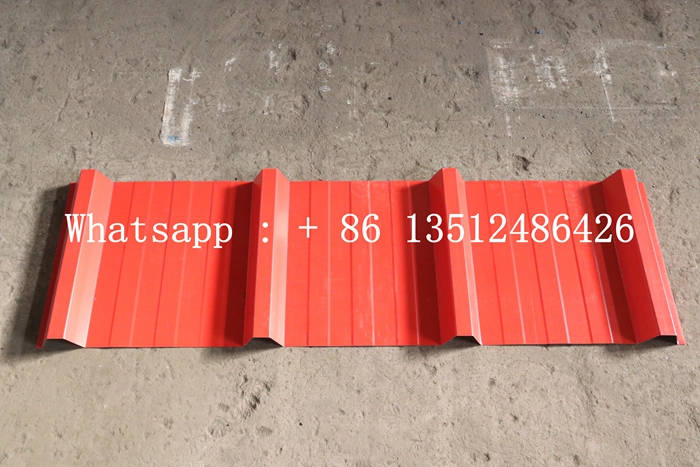

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Roofing Sheet Manufacturing Machine

Trapezoidal Roofing Sheet Manufacturing Machine

The trapezoidal roofing sheet manufacturing machine is divided into three parts, the roller forming part, the pressing part and the cutter part.

1. The roller forming part is driven by a motor, and the chain drives each roller to rotate.

2. In the pressing part, the hydraulic cylinder drives the mold to move up and down, which can press the color steel into many sections, shaped like glazed tiles.

3. The cutting knife part is driven by a hydraulic cylinder to move up and down, which can cut off colored steel tiles.

The production process of the trapezoidal roofing sheet manufacturing machine is as follows: the colored steel plate enters the roller forming part. After forming, it goes to the pressing part and is pressed into equidistant sections. The cutter is responsible for cutting to a fixed length.

Trapezoidal Roofing Sheet Manufacturing Machine

Specification

No. |

Number |

Trapezoidal Roofing Sheet Manufacturing Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 20 |

| 19. | Size | 9500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Advantages

1. Excellent weather resistance - service life not less than fifty years

2. Outstanding waterproof performance - no need for waterproof layer

3. Wind resistance and earthquake resistance - 90-degree building facade decoration is safe and reliable

4. Rich colors, novel personality, long-lasting and stable

5. Good fire resistance

6. Thermal insulation and thermal insulation - the roof tile with the highest thermal insulation performance

7. Good sound insulation performance

8. The glazed tile machine control system is simple to operate and has high precision. The cutting accuracy of each piece is less than 0.1mm, which meets the process requirements. The program runs stably and reliably.