Products

Steel Roofing Machine

Steel Roofing Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Steel Roofing Machine

Steel Roofing Machine

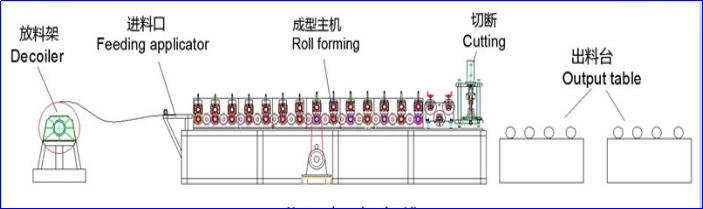

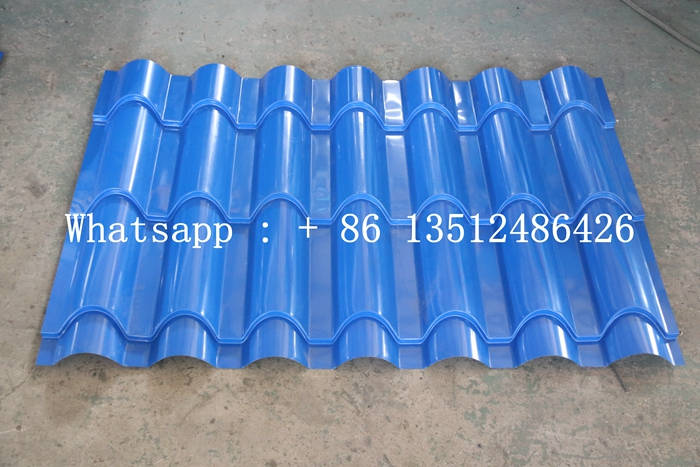

The steel roofing machine is a machine that consists of unloading, forming and cutting. The color plates it produces have a smooth and beautiful appearance, uniform paint patterns, high strength and durability. They are widely used in industrial and civil buildings, such as factories, warehouses, gymnasiums, and exhibitions. Roofs and walls of hotels, theaters, etc.

Steel Roofing Machine

Specification

No. |

Number |

Steel Roofing Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 16 |

| 19. | Size | 8000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Operate

1. Wear personal protective equipment

Before operating the tile press, you must wear necessary personal protective equipment, including safety helmets, work clothes, safety shoes, etc. These equipment can effectively protect the head, body and feet of workers and reduce the occurrence of accidental injuries.

2. Check the equipment

Before using the tile press, carefully check whether all parts of the equipment are intact, especially key parts such as transmission devices, cutting tools and hydraulic systems. If any damage or malfunction is found, report it to maintenance personnel immediately for repair.

3. Safe operating position

When using the tile press, workers should stand in a safe operating position and ensure that no people or other obstacles are close to the equipment. The operating location should be on a stable platform and away from areas that may cause danger, such as sliding mechanical parts and knives.

4. Ensure power supply safety

Before connecting the power supply, you must check whether the power line is intact and make sure the power switch is turned off. When connecting to the power supply, use a standard power cord and ensure that the line is well grounded to prevent current leakage and electric shock accidents.

5. Start the device

Before starting the tile press, make sure there are no debris or accumulations on the working platform. Before starting the device, you must wait for the device self-test to complete and ensure that each indicator light lights up normally. After starting the equipment, wait for the machine to reach normal working speed before operating.

6. Never squeeze by force

When operating the tile press, never forcefully squeeze out too much material. The operator should adjust the pressure and speed according to the load capacity and working requirements of the equipment to ensure the normal operation and safe operation of the equipment.

7. Materials are stored safely

To ensure safe operation, materials should be stored away from knives and extrusion areas. Materials should be placed flat and in designated locations to prevent them from slipping and accumulating and damaging the equipment.

8. Unload materials

When unloading materials, operators should be careful not to obstruct the sight and movement of other workers. Materials should be moved safely to designated areas and the work platform should be cleared in time for the next operation.

9. Turn off the device

At the end of the operation, turn off the power of the tile press in time and perform necessary cleaning and maintenance work. Workers must ensure that the equipment is in a safe condition before leaving the site to prevent accidental injuries and equipment failures.