Products

Steel Stud Roll Forming Machine

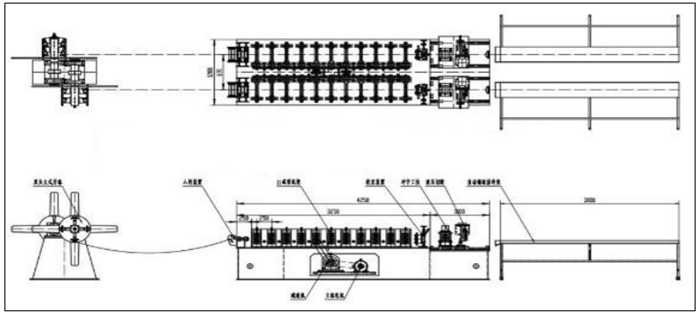

Steel Stud Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Steel Stud Roll Forming Machine

Steel Stud Roll Forming Machine

Steel stud is an integrated suspended ceiling

The fixed brackets inside are mainly used to fix the integrated ceiling

It is fixed and cannot be seen from the outside. The light steel keel ceiling has the characteristics of flatness and firm fixation. It is currently the first choice for integrated ceiling fixing brackets.

Steel stud roll forming machine is made of light steel and is used for ceilings

The main material of the suspended ceiling. It is connected to the floor through screw rods and is used to fix the ceiling or objects. It can also be used to fix suspended ceilings such as gypsum boards and wooden boards.

Steel Stud Roll Forming Machine

Specification

No. |

Number |

Steel Stud Roll Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.5t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 10 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. Improve indoor environmental conditions and meet functional requirements.

The decorative treatment of light steel keel ceiling can improve the indoor light environment, thermal environment and sound environment. It provides conditions for creating an indoor artistic environment and improving comfort. If a room has a suspended ceiling under the floor, the indoor sound environment can be improved by isolating air sounds to reduce impact sounds; laying thermal insulation and insulation materials in the suspended ceiling space, or using the suspended ceiling space to form a ventilation layer, can improve the indoor thermal environment; light steel The shape, color and texture of the keel ceiling can adjust the indoor light and improve the indoor light environment.

2. Beautify the space environment and improve the indoor decoration effect.

Ceiling decoration is easier for people to notice. It renders the environment and enhances the atmosphere from many aspects such as shape, space, light and shadow, color and material. Therefore, ceiling design should consider the combination of technology and art to achieve a perfect decorative effect.

3. Adjust the volume and shape of indoor space.

When the space enclosed by the building structural components is not ideal, the ceiling can coordinate and unify the volume and shape of the indoor space and enhance the integrity of the ceiling. To conceal equipment pipelines and structural components, the space in the ceiling can be used to install equipment pipelines required for lighting, air conditioning, ventilation, audio, fire protection, etc. In modern buildings, more and more equipment pipelines of various types generally need to be hidden in the ceiling. Make the top surface of the room tidy.