Products

Stud Roll Former Machine For Sale

Stud Roll Former Machine For Sale

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Stud Roll Former For Sale

Stud Roll Former For Sale

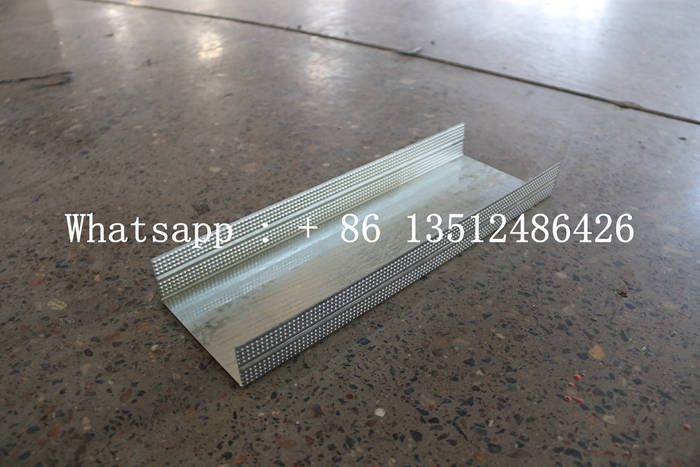

The keel is the core material of the integrated ceiling, and it bears all the weight of the entire gusset plate. Among them, light steel keel is a new type of decoration material, which is generally used for ceiling decoration and is widely used in hotels, office buildings and other places.

Stud Roll Former Machine For Sale

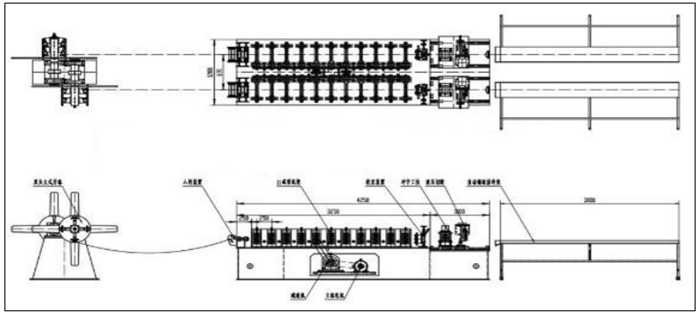

Specification

No. |

Number |

Stud Roll Former For Sale |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6.5*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.5t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 12 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. Its own mass is light: The texture of light steel keel is relatively light. If a 9 mm gypsum board set and a suspended ceiling are used, it is one-quarter of the weight of a plastered suspended ceiling.

2. Excellent fire resistance: Therefore, the light steel keel is usually a partition composed of 2 to 4 layers of gypsum boards, so its fire resistance is very good, reaching 1.0~1.6h, so the fire resistance of the light steel keel is Very good.

3. High construction efficiency: Because the light steel keel is relatively light, it can be constructed by assembly method, and the construction is relatively fast. Generally, professional construction workers can complete the partition of 3 to 4 meters in one day.

4. The structure is safe and reliable: The light steel keel also has the characteristics of high strength and high rigidity, so the ceiling made of it is very safe and reliable.

5. Light steel keel has good seismic resistance. Since the light steel keel and the surface layer are fixed with sliding connectors, when an earthquake occurs, the light steel keel can effectively absorb and disperse seismic energy, reducing the damage to the building. In addition, the flexibility and deformability of light steel keels also enable them to maintain good stability during earthquakes, ensuring the safety of the building.

6. Light steel keel also has the advantages of environmental protection and sustainable development. As a recyclable metal material, light steel keel will not cause environmental pollution during its production and application. At the same time, the use of light steel keels can also reduce dependence on traditional building materials, reduce the consumption of natural resources, and help achieve sustainable development of the construction industry.