Products

Metal Stud Forming Machine

Metal Stud Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Metal Stud Forming Machine

Metal Stud Forming Machine

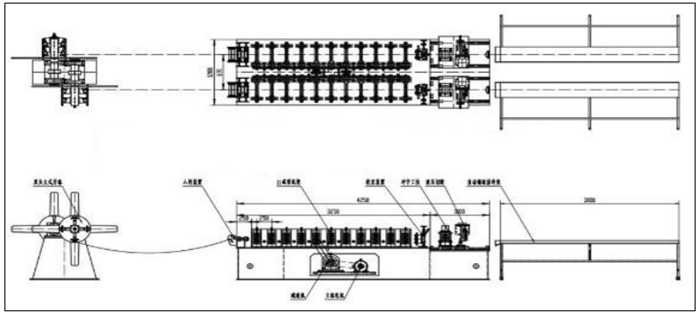

The metal stud forming machine uses strip steel as raw material and is formed by continuous cold rolling to produce complex cross-section profiles (products include: light steel keels, painted keels, cassette keels, various building profiles, steel structures, steel-lined door frame profiles, Highway guardrails, etc.)

1. The production scale is standard and accurate. We can also produce products according to any needs of our customers to meet the needs of the market. This production method has made the keel machine recognized in the market and expanded a large sales market. .

2. When the metal stud forming machine makes cold-formed profiles, the key is generally to select profiles based on strip steel.

3. The technical level of keel machines is also constantly improving with the progress of our country's times and the development of social science and technology.

Metal Stud Forming Machine

Specification

No. |

Number |

Metal Stud Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.5t |

| 8. | Produce speed | 45-60m/min |

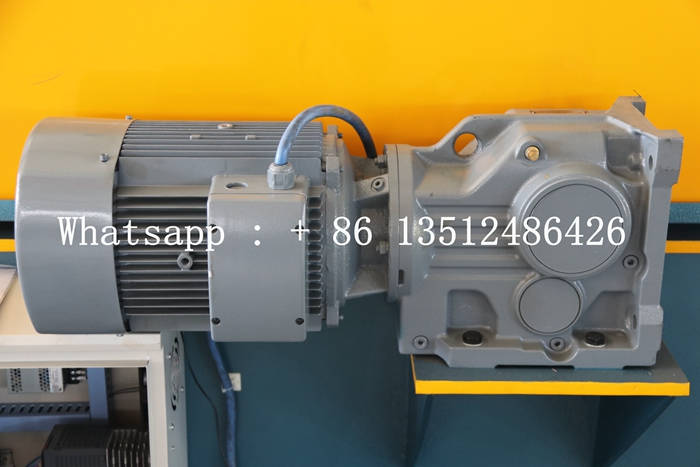

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 10 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Machine Composition

1. The metal stud forming machine is mainly controlled by PLC, and multiple safety protections are installed during normal production.

2. The bed of the metal stud forming machine is a steel plate welded part, which is tempered during operation, so as to eliminate internal stress and effectively avoid fuselage deformation.

3. The forming frame of the metal stud forming machine is of cast iron structure and has been tempered. High strength and long service life.

4. The material of the roller shaft of the metal stud forming machine is HCGr12 and has been quenched and tempered.

5. The transmission structure of the entire equipment is gearbox transmission, and the forming frame of the entire equipment has, which can effectively ensure the long-term and high-intensity operation of the equipment and a long service life.