Products

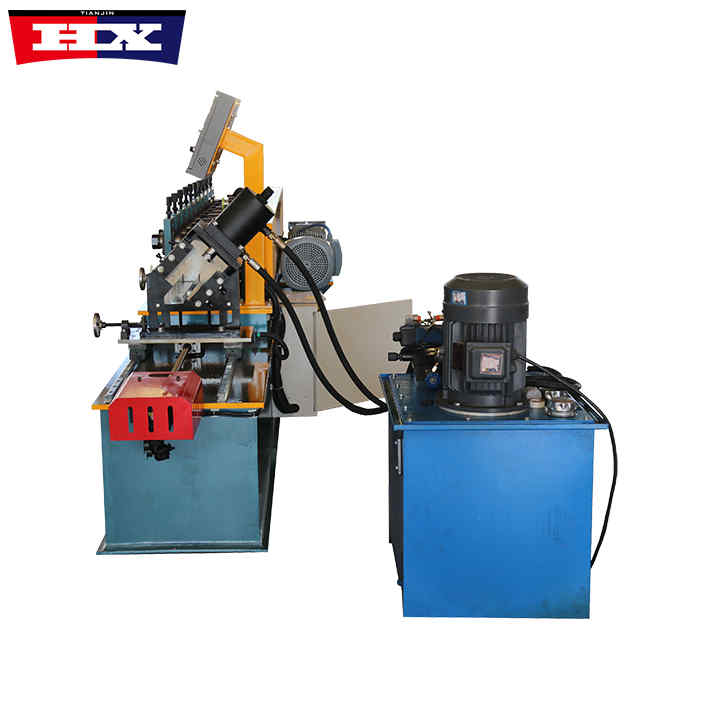

Metal Stud Roll Forming Machine

Metal Stud Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Metal Stud Roll Forming Machine

Metal Stud Roll Forming Machine

The metal stud roll forming machine is a mechanical equipment used to make lightweight steel keels. The keel machine can bend cold-rolled steel plates into C-shaped, U-shaped, L-shaped, and Omega-shaped steel keels, which are widely used in light steel structure construction, furniture manufacturing, industrial and civil construction and other fields.

Metal Stud Roll Forming Machine

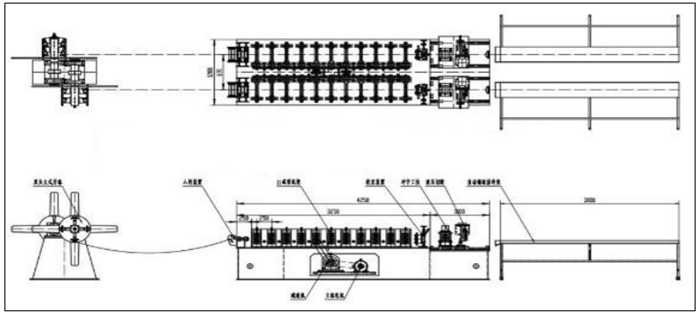

Specification

No. |

Number |

Metal Stud Roll Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.5t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

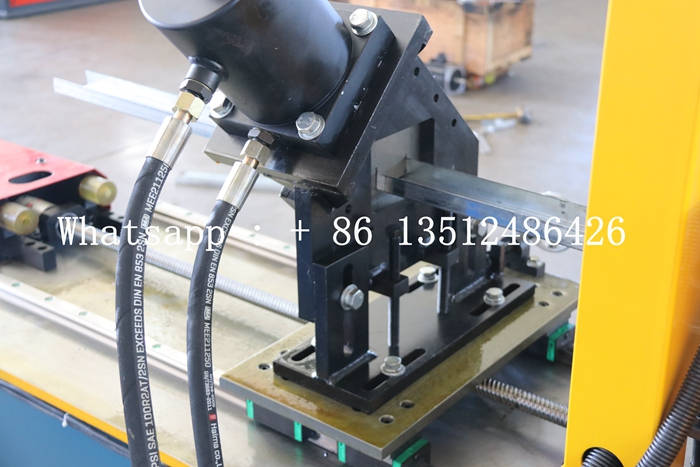

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 10 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Use

1. Preparation:

Prepare the steel plate, cut it to the appropriate size, and remove burrs from the edges.

2. Set up the keel machine:

Set the keel machine according to the required steel keel model, including the position and angle of the mold, machine head, cutting knife, etc.

3. Start the operation:

Put the steel plate into the keel machine, turn on the power, feed the steel plate into the machine head, and wait for the keel machine to automatically complete bending and cutting. Generally speaking, the keel machine can automatically complete the continuous bending and cutting of multiple steel keels, which greatly improves work efficiency.

4. Notes:

When using the keel machine, be sure to pay attention to safety. Operators must wear earplugs and safety glasses to protect themselves from noise and debris. At the same time, during use, the machine and work area should be kept clean to avoid safety accidents.

How To Choose

1. The quality of the machine: Choosing an excellent brand with good brand and guaranteed quality can reduce the cost of repair and maintenance.

2. Machine functions: Choosing a keel machine with complete functions and excellent performance according to your own needs can improve work efficiency and production efficiency.

3. After-sales service: After purchasing a keel machine, you need to consider the quality and guarantee of after-sales service so that problems encountered during work can be solved in a timely manner.

So choose us, we can meet all your requirements.