Products

Roof Step Tile Roll Forming Machine

Roof Step Tile Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Roof Step Tile Roll Forming Machine

Roof Step Tile Roll Forming Machine

Roof step tile roll forming machine have been widely used in the construction industry due to their high efficiency, high precision, multi-function, environmental protection and energy saving. By understanding the characteristics, advantages, application fields and usage precautions of this equipment, customers can better utilize the performance of the equipment, improve production efficiency, and create greater value for the enterprise. At the same time, during use, customers should also pay attention to the safety and maintenance of the equipment to ensure the stable operation of the equipment and extend its service life.

Roof Step Tile Roll Forming Machine

Specification

No. |

Number |

Roof Step Tile Roll Forming Machine |

| 1. | Operation style | Automatic |

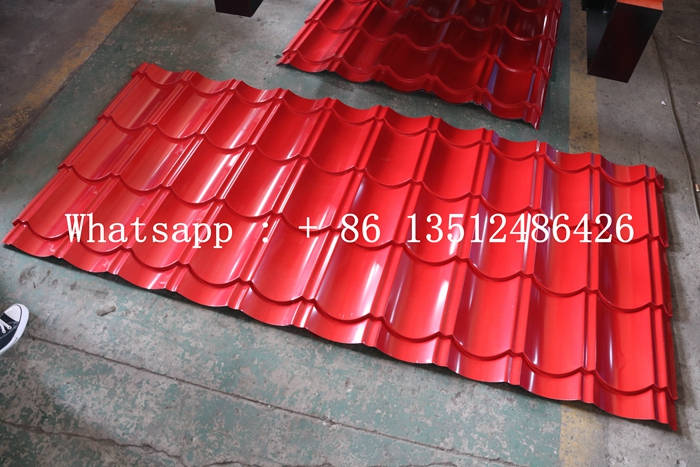

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 10 |

| 19. | Size | 5500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Notice

1. Comply with safety regulations: When operating the roof step tile roll forming machine, be sure to abide by safety regulations and wear safety protective equipment to ensure personnel safety.

2. Regular maintenance: Perform regular maintenance on the equipment, check the wear and tear of various parts of the equipment, and replace damaged parts in a timely manner to ensure the normal operation of the equipment.

3. Pay attention to the quality of raw materials: Use high-quality raw materials for production to ensure the quality and performance of the tiles.

4. Reasonably adjust parameters: According to production needs and raw material characteristics, reasonably adjust the operating parameters of the equipment to obtain the best production results.