Products

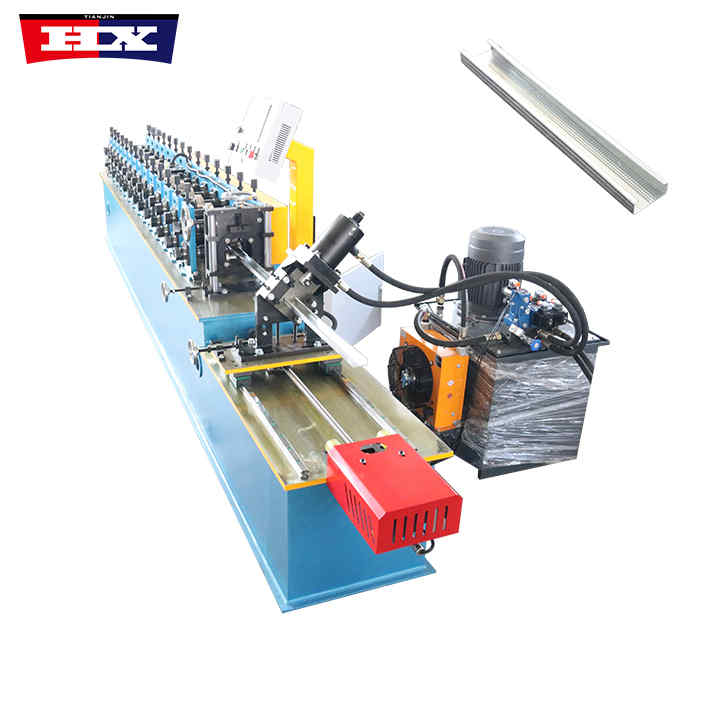

Track Roll Forming Machine

Track Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.4-1.2mm

Produce Speed : 45-60m/min

Port : Tianjin

Track Roll Forming Machine

Track Roll Forming Machine

As a high-quality building material, light steel keel occupies an important position in the construction industry with its unique advantages.

Track Roll Forming Machine

Specification

No. |

Number |

Track Roll Forming Machine |

| 1. | Suitable to process |

Color alu zinc steel coils |

| 2. | Transfer method | Gear transmission |

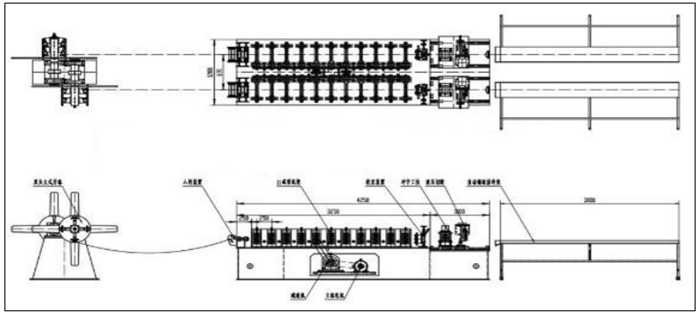

| 3. | Base frame | Type 300 Channel Steel Frame Welding Panel thickness 2mm, Q235 iron plate material (gantry milling plane processing) |

| 4 | Main frame | Square steel frame |

| 5. | Dimensions | 6.5*1.2*1.6m |

| 6. | Board size |

Memorial arch, thickness 35 mm (double bearings on front and rear arches) |

| 7. | Weight | About 3.6t |

| 8. | Produce speed | 45-60m/min |

| 9. | Engine power | 5.5Kw, the motor includes a type K reducer |

| 10. | Pump station engine | 5.5kw |

| 11. | Thickness of plate | 0.4-1.2mm |

| 12. | Cutting shape | Servo track cutting system 2.3kw servo motor power Platform track cut 30×30, ball screw diameter 3mm |

| 13. | Roller diameter | Φ50mm |

| 14. | Spacer | Φ70mm |

| 15. | Control system | PLC control ( Delta ) |

| 16. | Touch screen | Delta |

| 17. | Rolling stock | Cr12 steel bearing |

| 18. | Rows | 14 |

| 19. | Length tolerance | ±2mm |

| 20. | Voltage |

380v 50hz 3p or as customers ' requirement |

Advantages

1. Light steel keel has the characteristics of light weight and high strength. Light steel keel is made of high-quality continuous hot-dip galvanized strip as raw material and rolled through cold bending process. It has excellent mechanical properties and structural stability. Compared with traditional wooden or masonry keels, light steel keels are lighter in weight, which makes them more convenient and efficient during construction and installation. At the same time, the high strength characteristics of light steel keels ensure that they can withstand large loads and pressures, thereby ensuring the stability and safety of the building.

2. Light steel keel has excellent fire resistance. Since the light steel keel itself is not easy to burn, and the galvanized layer on its surface also has a certain degree of fire resistance, partitions or ceilings composed of light steel keels can maintain stability for a long time in a fire, effectively delaying the spread of the fire. In addition, light steel keels can also be used in conjunction with fireproof panels to form a more complete fireproof system and improve the overall fireproof level of the building.

3. Light steel keel has good sound insulation and heat preservation properties. Since the internal space of the light steel keel is large, it can be filled with sound insulation materials or thermal insulation materials, thereby effectively improving the sound insulation effect and thermal insulation performance of the building. This is particularly important for buildings that need to create a quiet and comfortable environment or require energy-saving insulation.

4. Light steel keel has the advantages of simple construction and short construction period. The light steel keel adopts an assembly construction method, which can be flexibly combined and spliced according to needs, without the need for complicated wet operations. This not only simplifies the construction process and reduces the difficulty of construction, but also shortens the construction period and improves construction efficiency. In addition, light steel keels can also be used with a variety of panel materials to achieve diverse decorative effects and meet different architectural styles and design needs.