Products

Corrugated Sheet Forming Machine

Corrugated Sheet Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Corrugated Sheet Forming Machine

Corrugated Sheet Forming Machine

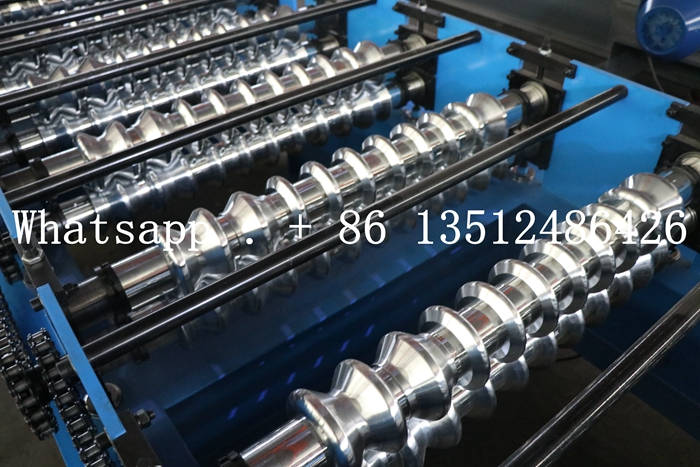

1. Efficient production: The corrugated sheet forming machine adopts advanced pressing technology and can quickly and accurately complete the tile pressing work. The equipment is equipped with an efficient power system, which can achieve continuous and stable production, greatly improving production efficiency.

2. Diversified pressing: This corrugated sheet forming machine has a variety of pressing molds, which can produce tiles of different specifications and shapes to meet different building needs. At the same time, users can also customize molds according to actual needs to achieve personalized production.

3. Easy to operate: The corrugated sheet forming machine adopts a humanized operating interface and control system, making the operation easier and more intuitive. The equipment is also equipped with complete safety protection measures to ensure safety during operation.

4. Sturdy and durable: The corrugated sheet forming machine adopts high-quality materials and advanced production technology, and has high wear resistance, corrosion resistance, impact resistance and other properties, ensuring the service life and stability of the equipment.

Corrugated Sheet Forming Machine

Specification

No. |

Number |

Corrugated Iron Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

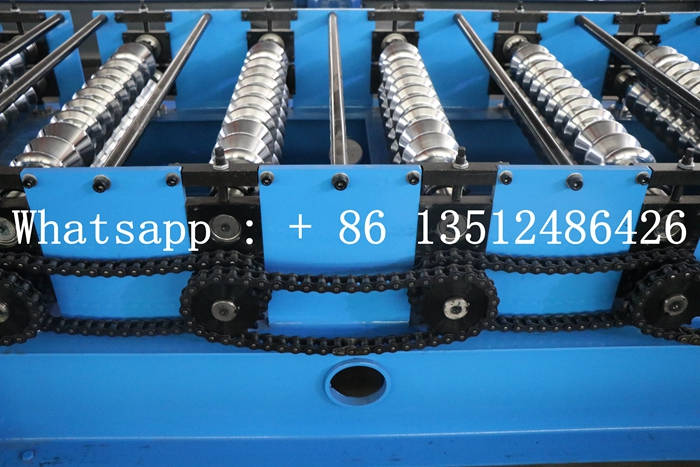

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 22 |

| 19. | Size | 10500mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Maintenance

1. Regularly check whether the fasteners of the equipment are loose. If they are loose, tighten them in time.

2. Lubricate the lubrication parts of the equipment regularly to ensure smooth operation of the equipment.

3. Regularly check whether the electrical system of the equipment is normal. If there are any abnormalities, deal with them in time.

4. Regularly clean dust and debris inside and outside the equipment to keep the equipment clean and hygienic.

5. Conduct comprehensive inspections and maintenance of equipment on a regular basis to detect and deal with potential problems and failures in a timely manner.

Application

The corrugated sheet forming machine are widely used in various construction fields, such as industrial plants, warehouses, agricultural greenhouses, residences, etc. The profiled tiles it produces have the advantages of beauty, durability, waterproofing, fireproofing, etc., and are favored by the majority of users. At the same time, this equipment is also suitable for producing various specifications of color steel tiles, corrugated tiles and other building materials, providing the construction industry with more choices.