Products

deck floor roll forming machine

deck floor roll forming machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

deck floor roll forming machine

deck floor roll forming machine

It is mainly composed of a combination of steel and concrete and has the advantages of high strength, good plasticity and toughness, fire resistance, and easy processing and installation. Floor decking has a wide range of applications, including industrial buildings, public buildings, commercial buildings, residential buildings, etc. It is especially suitable for large-span, high-rise and special-structure buildings. This building material has been widely used in the construction field due to its high strength, good plasticity and toughness, good fire resistance, easy processing and installation, economical and environmentally sustainable.

deck floor roll forming machine. The types of floor decking include open floor decking, closed floor decking, disassembly-free steel truss floor decking, etc. Open floor decking, also known as corrugated web-type steel-concrete composite structure, has high strength, good plasticity and toughness, and its fire resistance is very good. It is suitable for occasions with high fire protection requirements such as high-rise buildings and public places. Closed floor decking has the characteristics of light weight, high strength, and good seismic resistance, and is widely used in the field of steel structure construction. The disassembly-free steel truss floor deck has the advantages of waterproof and moisture-proof, stable and reliable, anti-corrosion and insect-proof, and simple construction. It is widely used in tunnels, underground passages, villas, commercial buildings, industrial buildings, bridges, residences, apartments, schools, public facilities, etc. All construction cast-in-place locations.

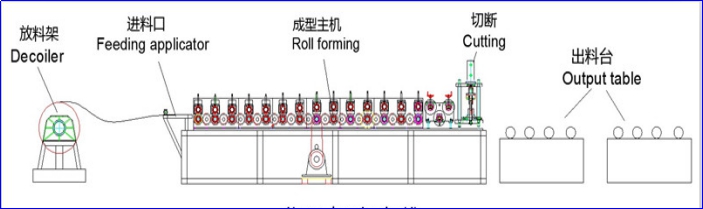

Deck Roll Former Machine

Specification

No. |

Number |

Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

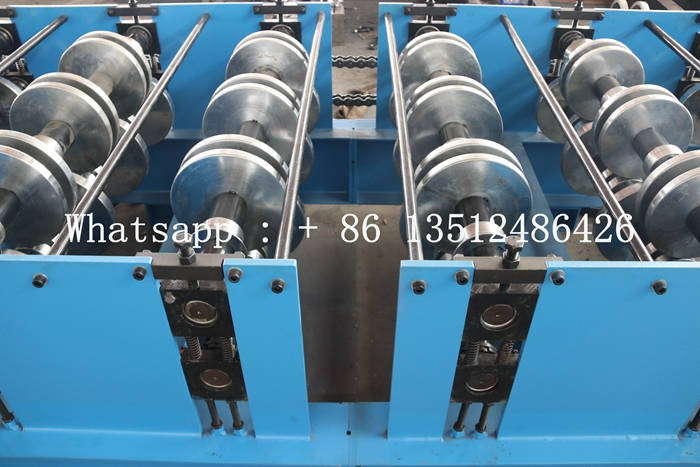

Parts of machine

|

|

Name: Motor drive Brand: Shanghai Lichao Main motor size :5.5KW |

|

Name: Hydraulic station power Hydraulic station power :4Kw |

|

|

|

Name: Shearing Mechanism It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12,quenching treatment |

Features

1: deck floor roll forming machine. It adapts to the requirements of rapid construction of the main steel structure, can provide a firm working platform in a short time, and can adopt the flow construction of laying profiled steel plates on multiple floors and pouring concrete slabs in layers.

2: Deck Roll Former Machine. During the use stage, the floor deck serves as the tensile steel bar for the concrete floor slab, which also increases the stiffness of the floor slab and saves the amount of steel bars and concrete.

3: Deck Roll Former Machine. The embossing on the surface of the profiled board creates the maximum bonding force between the floor decking and the concrete, making the two form a whole. Together with the stiffening ribs, the floor decking system has a high bearing capacity.

4: Deck Roll Former Machine. Under cantilever conditions, the floor decking only serves as a permanent formwork. The length of the overhang can be determined according to the cross-sectional characteristics of the floor deck. In order to prevent the cantilever plate from cracking, it is necessary to add negative reinforcement at the support according to the design of the structural engineer.